What Is PVA Filament and What Is It Used For?

If you're new to 3D printer technology, chances are you've heard of PVA filament. It's a popular material used for 3D printing due to its superb water solubility. It supports intricate 3D models during the process of printing with FDM dual extruder machines. Because PVA can create detailed prints, it’s a very popular choice among hobbyists and professionals.

So we embark on discovering what PVA filament is, its different benefits, and how you can best utilize it to generate amazing 3D prints.

What Is PVA Filament?

PVA, polyvinyl alcohol, is a well-known filament for 3D printing. Being highly water-soluble, it is used mainly as a support material in dual extrusion 3D printing. It easily dissolves in tap water. PVA offers individuals greater design freedom for parts with complex geometries. It’s also compatible with PLA, PETG, and nylon.

Benefits of Using PVA Filament

PVA is a much-loved water-soluble filament due to the following advantages:

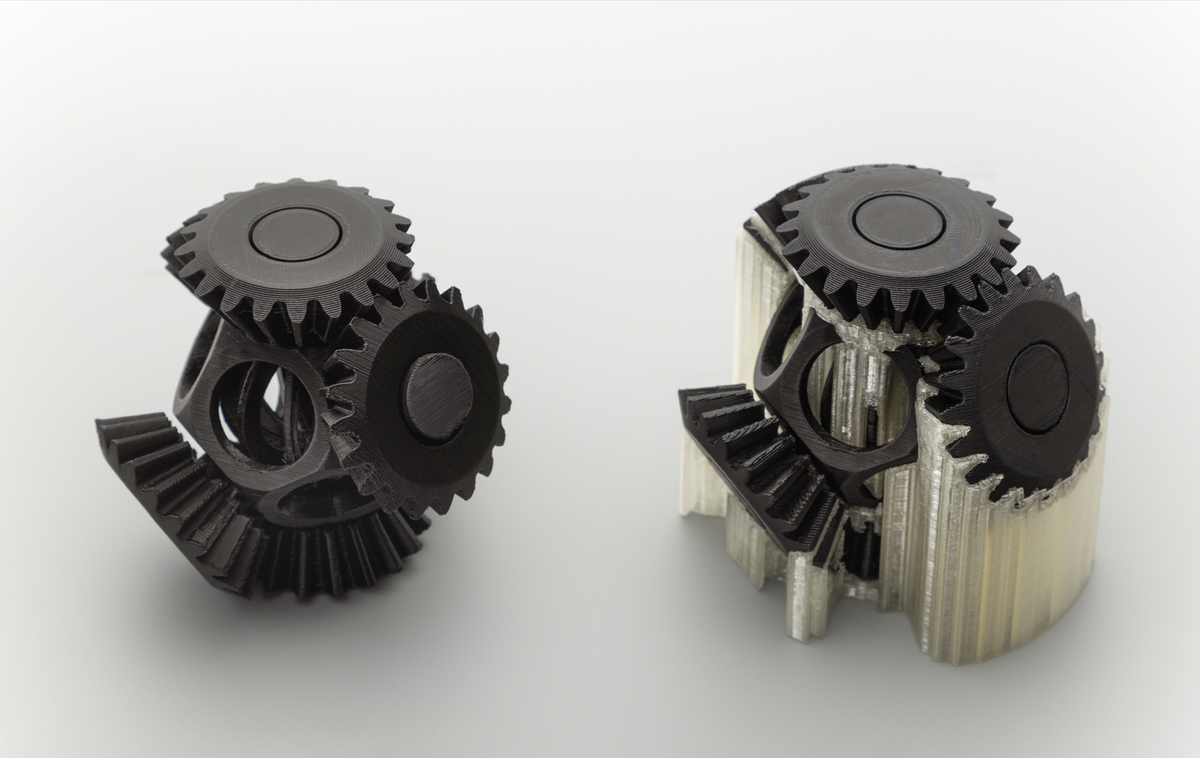

- Complex Designs: Enables printing overhangs, hollow structures, and intricate models.

- Smooth Finishes: Leaves no marks after dissolving, unlike traditional supports.

- Ease of Usage: Easy dissolution in water, thereby reducing manual cleanup. ·

- Versatile: Friendly with the most popular filaments or dual-extrusion printers like Snapmaker Artisan.

How to Use PVA Filament Effectively

Using PVA is quite simple. You can easily print by following the steps:

- Printer Compatibility: You need to ensure your 3D printer supports the dual extrusion feature. Good models are the Snapmaker 2.0.

- Storage Rule: Always store PVA in a tightly closed, dry container because the material can soak in humidity, which can result in print damage.

- Heating Recommendation: We recommend using the heated bed at a set temperature of around 45-60 °C, while the extruder is set to 190-210 °C for optimal results.

- Dissolving Procedure: After printing, your model will be placed in lukewarm water. Allow for soaking for several hours, stirring the water now and then to help dissolve.

Challenges and Considerations

3D printing support materials, as is the case with Polyvinyl Alcohol (PVA), are not disposable but have the most significant attributes until some shortcomings are encountered.

- Moisture sensitivity: The polymer is so hygroscopic that it easily pulls moisture from the air when it is open, leading to poor layer-to-layer adhesion, inconsistent extrusion, and, finally, clogs in the nozzle. The conclusion is that it's better to store it in a dry, airtight container. A better option will be to incorporate the desiccant packs together with the polymer, as also suggested by the author. This ultimately helps us with good prints and fewer problems in the future.

- Printer Requirements: PVA works best when paired with another filament like PLA or PETG that requires a dual-extrusion printer. Such a printer can run two materials simultaneously, allowing for more flexibility with PVA and cleaner support removal. Yet, generally, they are more expensive and complex to operate than ordinary single-extrusion models.

Even though these challenges exist, PVA remains an amazing contender for printing precise models with clean dissolvable supports, with the exception of additional considerations that would entail a suitable printer and storage method.

The Best 3D Printer for PVA Filament

If you are planning to work with PVA filament, ensure your 3D printer is compatible with the dual-extrusion mode and is manufactured for reliability in performance.

If it's PVA filament you want to be using for dissolvable supports, Snapmaker J1S would come highly recommended as one of the best printers. It has an Independent Dual Extruder (IDEX), which allows users to print with two materials at the same time; this is great for combining PLA or PETG with PVA. Besides, it can be applied for using dual-material, breakaway, and dissolvable-support printing modules, making it perfect for using functionalities associated with the complex models that require the clean removal of supports.

The Snapmaker J1S is also the fastest IDEX 3D printer on the market, with a maximum print speed of 350mm/s and acceleration up to 10,000mm/s². This means you get faster prints without sacrificing quality. Its hands-free XY offset calibration, tool-free bed levelling, and easy Z-offset adjustment make setup simple and user-friendly.

It’s also designed for a smooth user experience, featuring a 5" touchscreen and a custom IDEX slicer in Snapmaker Luban, making it easier to manage dual-material prints. The enclosed build chamber supports stable temperature control, crucial when printing with moisture-sensitive materials like PVA.

Conclusion

PVA is a popular 3D printing support material amongst professionals. It has an incredible water solubility, and it supports various complex designs. You must store it in a dry container and choose the ideal temperature for perfect printing. Try out PVA for your next project and explore more of our PVA-supporting printers.