Is TPU Toxic to 3D Printing? The Definitive, Evidence-Based Guide for 2025

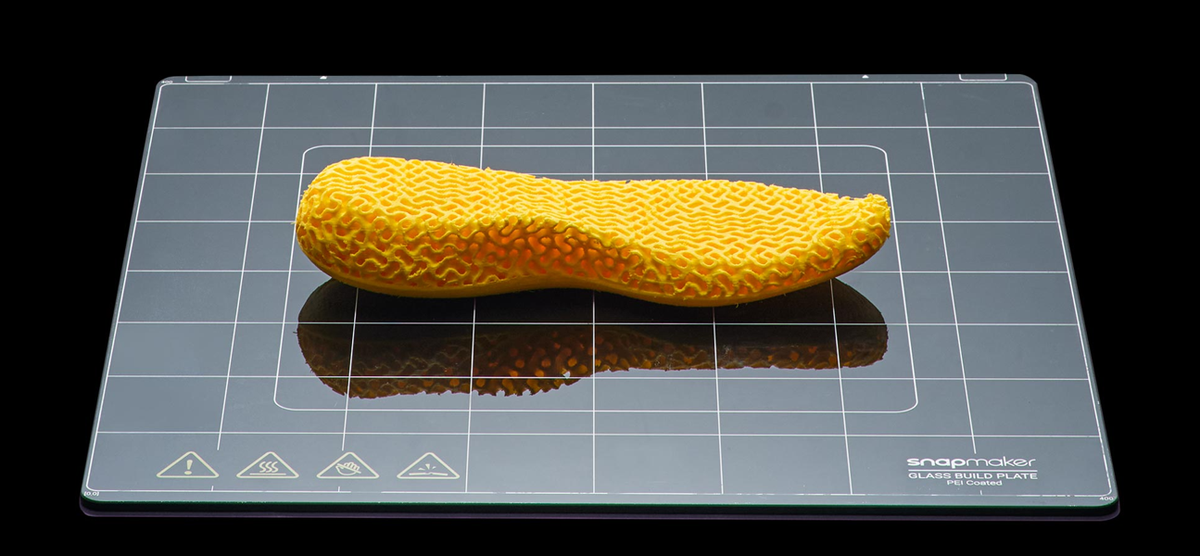

You pull out a spool of TPU because you want a flexible phone case or a sturdy drone part. The printer is ready, but before you hit start, a question lingers. Can we run this print indoors? TPU, short for Thermoplastic Polyurethane, is popular because it bends, resists wear, and lasts. Still, when it heats up in the hot end, it gives off more than melted plastic. Fine particles and gases slip into the air.

That’s what we’ll explore here: what TPU is, what researchers have found about its emissions, the risks they carry, and the practical steps you can take to keep your workshop safer. Tiny particles and chemical vapors enter the air.

This guide breaks it down: what TPU really is, whether TPU filament is toxic, what research says about its emissions, the real risks to you, and clear steps to keep your printing space safe.

What TPU Is and Why It Emits Particles and Fumes

TPU (Thermoplastic Polyurethane) belongs to a family of plastics prized for elasticity, abrasion resistance, and resilience. Makers use it for wearables, protective cases, and mechanical parts. You can learn more about its general properties in our TPU Filament 3D Printing Guide.

When TPU is pushed through a printer’s hot end, it passes its melting point. At that stage, thermal decomposition begins, and gases escape into the air. This is why you may notice faint odors or haziness.

Key terms to know:

- UFP (Ultrafine Particle): Particles smaller than 100 nanometers that reach deep in the lungs.

- VOC (Volatile Organic Compound): Chemicals that evaporate at room temperature; measured as TVOC.

- ACH: Air Changes per Hour, a measure of ventilation.

- HEPA filters: Capture particles.

- Activated carbon filters: Absorb VOCs.

What the Science Says About TPU Emissions

Scientific research confirms TPU is not emission-free. A peer-reviewed study in MDPI ranked TPU in the moderate-to-high category for ultrafine particle release. While less severe than ABS or Nylon, it is notably more than PLA. So is TPU toxic? Well, yes.

TPU does not emit much styrene, a well-known irritant found in ABS. Instead, it produces other compounds. Researchers frequently identify the release of isocyanates and other compounds like carbon monoxide. Both are known occupational health hazards studied for their long-term effects.

Another consistent finding is the temperature link. Higher nozzle and bed temperatures produce more UFPs and VOCs. A hotter print equals heavier emissions. That means the material itself is not the only factor; how you print matters just as much. Understanding this gives makers control over both print quality and air quality.

Practical Tips for a Safer TPU Printing Setup

Now that we understand what TPU emits and why, the next step is to determine whether TPU is toxic to print. The goal isn’t to avoid TPU; it’s too useful for that, but to set up your workspace so you can print with confidence. The following tips focus on simple, effective ways to cut down exposure and keep your air cleaner.

Control the Air While 3D Printing

- The best strategy is to control emissions at the source. Venting outdoors is the gold standard. A vented enclosure channels fumes directly outside, preventing them from circulating indoors.

- If venting is not realistic, filtration becomes the alternative. The key is combining an enclosure with a powerful air purifier. A standalone purifier in a large room will help, but it cannot capture fumes at their source.

Snapmaker offers integrated solutions. The Snapmaker 2.0 Enclosure and the enclosures designed for Artisan and Ray models seal the printing space. Pairing these with the Snapmaker Air Purifier delivers a strong defense. The purifier has HEPA and carbon filters. One traps tiny dust, the other traps gas. Together, they keep the air clean so you can print TPU with less worry.

Operate Smartly With TPU Filament

Your workspace setup plays as big a role as your equipment. Avoid printing TPU in bedrooms, kitchens, or living areas. Choose a dedicated workshop, garage, or ventilated room where airflow can be managed.

Keep enclosure doors closed while the printer runs. Opening them mid-print lets emissions spread before the filter does its job. When the print stops, do not open the door right away. Keep the fan or filter on for 20 to 30 minutes first. This clears any lingering fumes or fine particles.

Print settings matter too. Always start at the lower end of the recommended nozzle temperature for your TPU brand. Lower heat reduces unnecessary off-gassing without sacrificing quality. By combining a suitable location, consistent enclosure use, and smart temperature management, you minimize exposure while enjoying TPU’s flexible performance.

Debunking Common Myths About TPU Safety

False assumptions often lead to risky practices. Clearing them up helps makers print with facts, not guesses.

Myth 1: "If I can't smell it, it's not a problem."

Reality: Smell is not a reliable guide. UFPs have no odor, yet they reach deep into the lungs. Some VOCs also escape notice by smell alone. Ventilation is essential even when the air seems clear.

Myth 2: "A standard HEPA air purifier in the room is good enough."

Reality: A HEPA purifier helps, but only reduces particles floating in open air. It does not stop emissions at the printer. Plus, VOCs pass through HEPA filters untouched. Activated carbon is required. The best setup captures emissions directly from the enclosure and filters them fully.

Myth 3: "FDA-compliant TPU is food-safe to 3D print."

Reality: Raw TPU may meet standards, but printing changes the material. Micro gaps trap bacteria, printer residues contaminate surfaces, and dyes add uncertainty. Consumer-printed parts should not touch food directly.

Conclusion: Print Flexibly, Print Safely

TPU is tough, flexible, and practical, but it is not completely clean when printed. Studies show it gives off fine particles and a mix of VOCs, though at lower levels than ABS. The good news is these emissions don’t have to stand in your way. With the right setup, they are manageable.

A safe approach is simple: contain the print with an enclosure, capture the particles with a HEPA filter, and handle the gases with activated carbon. Add smart habits, like good room choice, closed doors, and running filtration after the print, and you create a safer environment without losing any of TPU’s advantages.

Want to take the next step? Check out Snapmaker’s Enclosure and Air Purifier for your TPU projects.