3MF vs. STL: The Difference Explained (And Why 3MF Is the New Standard)

When you’re ready to print, you go to save or download your 3D model and you’re faced with a choice: the familiar .stl or the newer .3mf. If you're confused, you're not alone.

For decades, the STL file has been the default. But it's a file format from 1987, and it has become a bottleneck for modern printing. Its persistence is a classic case of "technological inertia"—we use it because we've always used it.

Today, the 3D printing industry is bifurcated: the hobbyist world still relies heavily on STL, while the professional and industrial sectors have decisively moved to 3MF (3D Manufacturing Format).

This isn't just a simple upgrade; it's a strategic shift from simple prototyping to a "smart" project file that contains your entire manufacturing intent. This article will compare them directly and show you why 3MF is the new standard.

3MF vs. STL: A Head-to-Head Comparison

The difference is clearest when you see it side-by-side.

Feature | STL (The Old Standard) | 3MF (The Modern Solution) |

Saves Slicer Settings | No | Yes |

Saves Color & Material Data | No | Yes |

Saves Multi-Part Assemblies | No | Yes |

Includes Model Units | No (Error-prone) | Yes (Unambiguous) |

Error Robustness | Prone to errors | Error-free by design |

Extensible (Future-Proof) | No (Static) | Yes (via Extensions) |

File Size | Large & Uncompressed | Small & Compressed |

Consortium Backing | None | Yes (Microsoft, HP, etc.) |

Official Standard | De facto only | Yes (ISO/IEC 25422:2025) |

What is an STL File? (The Old Standard)

A 1980s Solution for 1980s Hardware

STL (an acronym for Stereolithography) was a "product of necessity" in 1987. It was designed for the very first 3D printers and the limited computing power of the time. Its only job was to describe a 3D object's surface geometry using a mesh of triangles (tessellation).

Think of it as a digital blueprint that shows the shape of the model and absolutely nothing else.

The Pros and Cons of Simplicity

STL's one advantage is universal compatibility. Because it's so old and simple, every 3D program in history can read it.

But that simplicity is its critical flaw. The STL format suffers from "data poverty." It has no way to store crucial information like color, materials, printer settings, or even what units (inches or mm) the part was designed in.

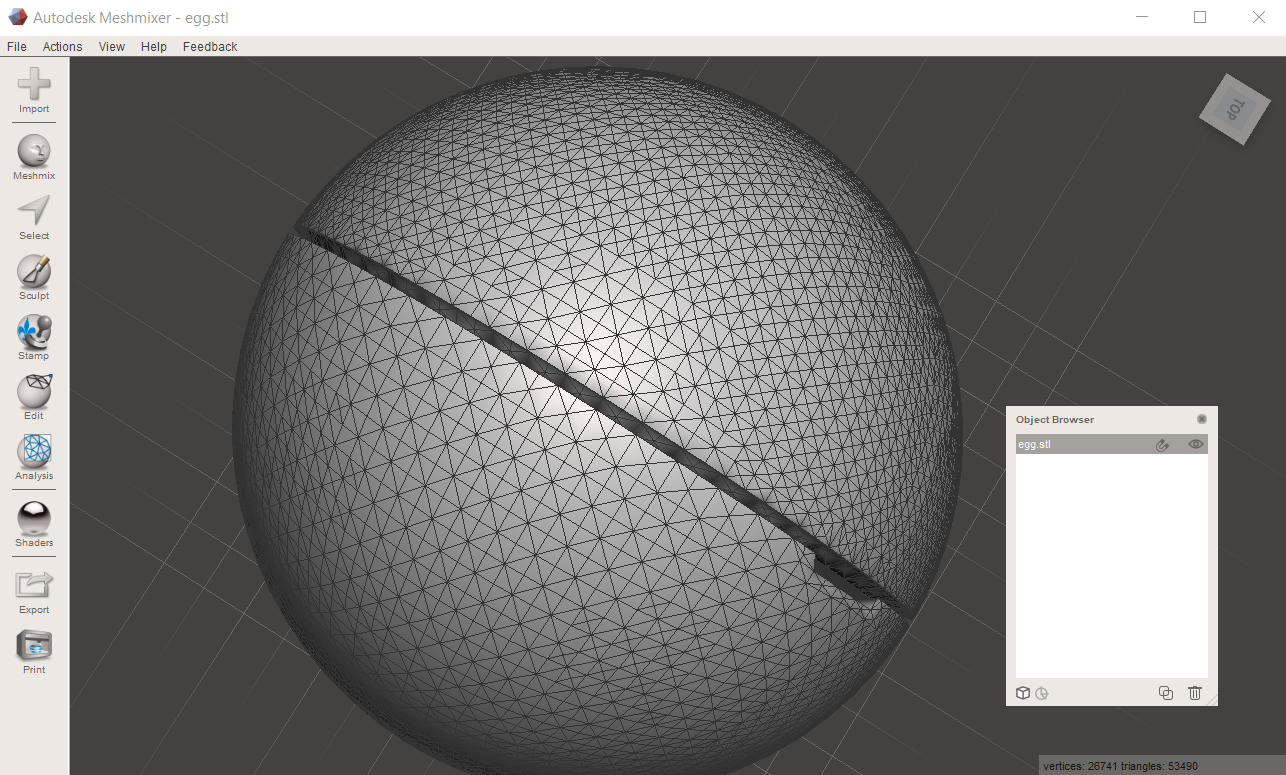

This leads to the "hidden cost" of the STL workflow. That "destructive" conversion from a perfect CAD model into a triangle mesh often creates errors:

- Holes in the mesh

- Flipped normals

- Non-manifold (geometrically impossible) edges

This forces you to waste time in repair software like Meshmixer or Netfabb just to get a "watertight" file that’s ready to print.

What is a 3MF File? (The Modern Solution)

A "Smart" File for Modern Manufacturing

3MF (3D Manufacturing Format) was introduced in 2015 to solve every one of STL's problems. It was created by the 3MF Consortium, a group of industry leaders including Microsoft, Autodesk, HP, Siemens, and Stratasys, who all agreed that the industry needed a better, open and extensible standard.

How It Works: The "Digital Thread"

The most important concept to grasp is this: a .3mf file is not just a model. It’s a "container," like a .zip file, that holds the entire "digital thread" of your project.

Inside this single 3MF file, you can find:

- The 3D Models: It can hold multiple objects, each as its own part, with their exact positions and assembly information.

- Slicer and Printer Settings: The game-changer. It saves your supports, infill, layer heights, and printer profile all in one file.

- Color and Material Data: 3MF is built from the ground up to handle multi-color and multi-material printing.

- Human-Readable XML: Unlike a binary STL, a 3MF's core data is XML, which developers can read and debug.

- Smaller File Size: 3MF is naturally compressed. It also stores vertex data more efficiently (storing each vertex's coordinates once instead of redundantly for every triangle that shares it), resulting in much smaller files.

- Error-Free by Design: It's built to prevent the common mesh errors that plague STLs.

3MF's Secret Weapon: A Future-Proof Format

The biggest difference between STL and 3MF is that STL is static, while 3MF is "extensible."

The 3MF format was designed to evolve with the industry. Its core can be expanded with official "extensions" to support new, groundbreaking technologies that are impossible with STL.

- Beam Lattice Extension: This allows for the hyper-efficient saving of complex lattice structures, which are critical for lightweighting parts in aerospace or creating medical implants.

By the numbers: A complex lattice structure that would be an 8MB STL file can be represented in a 3MF file as just 11KB. That's a reduction of over 99%. - Volumetric Extension: This unlocks the future of printing "functionally graded materials"—for example, a single part that is rigid on one end and gradually becomes flexible on the other.

- Secure Content Extension: This allows for file encryption, protecting your intellectual property (IP) when you send a design to a third-party print service.

How 3MF Upgrades Your 3D Printing Workflow

From "Tribal Knowledge" to a Codified Process

Think about the last time you shared an STL. You probably had to send an email or message with it: "Make sure to print it at a 45-degree angle, use tree supports, and set infill to 20%..." This is called "tribal knowledge." It's external to the file and easily lost or misinterpreted.

A 3MF file "codifies" this knowledge. It saves your entire slicer setup inside the file. When you share a 3MF, you are sharing a complete, ready-to-print job. The recipient opens it, and your exact orientation, supports, and printer settings are all there, ensuring a perfect, repeatable result every time.

Why 3MF is Essential for Modern Slicers

This is why modern slicers, including Snapmaker Orca, use 3MF as their default project file format.

This is an intentional design choice. When you use Snapmaker Orca and hit "Save," you are saving a .3mf file. This single file "remembers" everything:

- That you're using a Snapmaker printer.

- What your multi-extruder settings are.

- All your fine-tuned print profiles.

- The exact orientation of all parts on the build plate.

- Your custom-painted supports.

This allows you to close the project, re-open it a week later, and pick up exactly where you left off with zero rework.

3MF vs. STL: Frequently Asked Questions

Is 3MF always better than STL?

Yes. For 3D printing, 3MF is technically superior in every way. The only reason to ever use an STL is if you are forced to use very old, outdated software (from before 2015) that cannot open a 3MF.

Can I convert 3MF to STL?

Yes, easily. If you need to export an STL for an older program, just open your .3mf file in any modern slicer (like Snapmaker Orca) and choose File > Export > Export as STL. This will strip away all the "smart" data (settings, color, etc.) and leave you with just the raw 3D mesh.

What's the difference between 3MF, STL, and STEP?

This is a critical distinction:

- STEP: This is a "solid" CAD file used for designing a part (e.g., in Fusion 360). It contains perfect, mathematical geometry.

- STL/3MF: These are "mesh" files used for printing a part. They are a "destructive" but necessary translation of that perfect geometry into a collection of triangles that a slicer can understand.

The best workflow is: Design in CAD (saving as a STEP file) and Export as a 3MF file for slicing and printing.

Conclusion

While STL was the pioneer, its time as the professional standard is over. 3MF is superior in every practical way: it's smaller, more reliable, contains all your settings, and is future-proof.

If you need one final, definitive reason, here it is: 3MF was standardized by ISO and IEC as ISO/IEC 25422:2025 — Information technology — 3D Manufacturing Format (3MF) specification suite. This solidifies its place as the industry's official successor to STL.

For any serious 3D printer user, switching to a 3MF-based workflow isn't just a preference; it's a strategic imperative for faster, more reliable, and more innovative printing.

The best way to understand the power of 3MF is to use it. Download Snapmaker Orca and try saving your next print as a 3MF project file. You'll immediately see how it streamlines your entire workflow, letting you focus on creating, not just managing files.