What Is Purge in 3D Printing? Tips to Reduce Filament Waste

Do you use more filament than expected when printing in many colors or materials? You are not alone.

In 3D printing, there is a process called purge. This means pushing out some filament to clean the nozzle. It happens before a print starts or when the printer switches color or material.

This sounds helpful, and it is. But sometimes, purge uses more filament than the model itself. That means more waste, longer print time, and higher costs.

In this blog, you will learn what a purge is, why it occurs, and how to minimize it. These tips will help save your filament, time, and money.

What Is Purge in 3D Printing?

Purge is the act of pushing filament through the nozzle to prepare it for printing. It clears old filament from the nozzle so new material flows out clean. This helps avoid clogs and color mixing.

You might see purge happen in a few ways:

- Purge line – A simple line printed at the edge of the bed to check and clean the nozzle.

- Purge tower – A tall waste structure made during color switches in multi-color prints.

- Purge bucket – A container used in some printers to collect extra filament during purging.

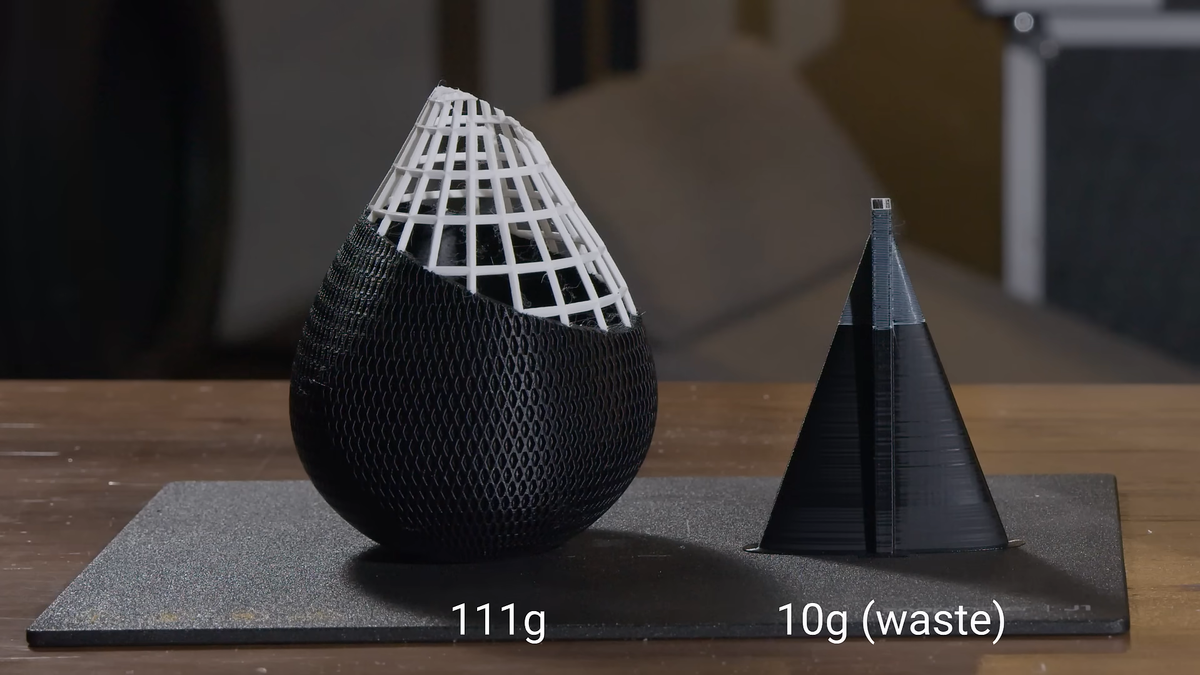

These methods are useful but also wasteful. A purge tower, for example, may use 10 to 20 grams of filament, or more. That’s a lot if your model is small.

Too much purge means longer jobs and higher material use. But without purging, you might see rough prints, color smears, or jams. So, you need to purge, but not too much.

Why Does Purge Matter?

Filament is not cheap. When your printer uses extra material for purge, your costs go up. That’s bad news if you print a lot or run a business.

Also, purging slows the whole process. Each switch adds time. For models with many changes, the job may take hours longer.

The goal is balance. Enough purge to protect the print, but not so much that you waste filament. Too little purge can cause bad prints. Too much costs time and money. You need a middle path.

Common Causes of Excessive Purge

In multi-color or multi-material printing, some purge is needed. But too often comes from these causes:

- Printer Design – One-nozzle printers need more purging during switches.

- Slicer Settings – Default purge amounts may be too high.

- Print Design – More color switches mean more purge. Complex designs waste more.

- Filament Type – Sticky or soft filaments like TPU need more cleaning.

- Nozzle Condition – Dirty nozzles need extra purge to keep prints clean.

New printers fix some of these issues. For example, the Snapmaker U1 has an innovative tool-changing system. It uses one nozzle per material. No need to clean one shared nozzle every time. That means fewer purges and more printing.

How to Reduce Purge in 3D Printing

You can’t stop the 3D printing purge, but you can shrink it. These easy tips help keep waste low and quality high.

Optimize Slicer Settings

Check your slicer’s purge settings. Most slicers let you change purge line size or tower height. Try reducing these amounts.

In the G-code, you can also lower how much filament comes out at the start. For instance, change G1 X60 E9 to G1 X30 E4 for less filament. That small change cuts waste in half. You still clean the nozzle, but use less filament.

Plan Prints Strategically

Think before you print. Try to design your models with fewer switches.

For example, print the base in one color. Then switch to another for the details. This reduces how many times the nozzle needs to purge.

If you can group parts by color or material, do that too. Less switching means less purging.

Maintain Your Printer

Clean nozzles print better and waste less. A dirty nozzle may need more purge to work right.

Use cleaning filament between prints. Remove buildup with a brush or needle. Keep your extruder healthy, and it will need less effort to stay clean during jobs.

The Future of Purge Reduction in 3D Printing

Better printers and software are changing how we purge.

Tool-changing systems use one nozzle per filament. That removes the need to clean a single nozzle every time.

Slicer tools are also smarter now. They calculate just the right amount of purge needed, no more, no less. Some printers even have sensors. These detect flow problems early and fix them without heavy purging.

Take the Snapmaker U1. It uses the SnapSwap™ system to change print heads fast. It can hold four different tools. This setup reduces the need for purge towers or lines. Just print and switch. Easy.

More printers may adopt this kind of design soon. It’s a cleaner way to print in many colors or materials.

Conclusion

Purge is important in multi-color 3D printing. It keeps prints clean and smooth. But too much purging wastes time, money, and filament.

You now know why purge happens and how to manage it. Try smaller purge lines. Plan your print jobs better. Keep your printer clean.

And keep an eye on new tech. Tools like the Snapmaker U1’s SnapSwap™ system are changing the game. They help users print better, with less waste.

Smart printing is not just about the model. It’s about the process, too. Reduce your purge. Save your filament. Print smarter.