The Art of Design: Snapmaker U1

How do you tell a story through Industrial Design?

How do you tell a story through Industrial Design?

Snapmaker U1 is a Fast, Precise, and Material-Efficient Multi-Color Printer with a Clean Aesthetic for Everyday Creators

In 2022, Snapmaker, known for its all-in-one machines, set out to enter the consumer 3D printer market with a more focused and accessible product. The U1 was designed to deliver fast, precise, and material-efficient multi-color printing in a form that fits comfortably into modern home environments. Instead of relying on bulky external AMS boxes, we developed an integrated toolhead-swapping system to simplify multi-color printing. This approach reduces both complexity and footprint—making advanced printing more practical.

Background & Challenge

Snapmaker originally built its reputation on all-in-one machines, but as the company looked to grow, we saw an opportunity to reach a broader audience—especially home users and creative hobbyists. To succeed in the consumer 3D printer market, we had to rethink how multi-color printing could fit into everyday life.

We identified a few key challenges:

⚙️ Most multi-color printers relied on bulky, expensive AMS systems that were difficult to set up and awkward to integrate into the printer body.

⚙️ Switching materials was slow, wasteful, and expensive—each change meant purging filament, wasting plastic, and losing time.

⚙️ Frequent print failures and the need for manual calibration frustrated users, especially beginners.

⚙️ Many existing machines were too noisy or industrial-looking, making them a poor fit for homes, studios, or classrooms.

With these pain points in mind, we set out to design a printer that made advanced features feel simple and approachable—something that felt right at home in a modern living space, without compromising performance or reliability.

Snapmaker U1 Technical Innovation

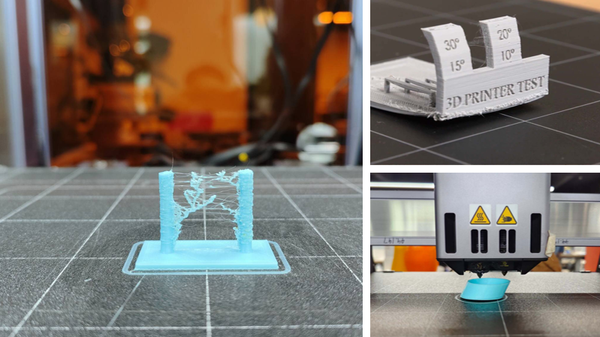

Multi-material 3D printing opens up new creative possibilities, but it can be highly inefficient when using a single nozzle to switch between materials. Every time the printer changes materials, it needs to purge the previous filament and prime the new one to maintain color and consistency. This process wastes a lot of filament—through purge lines and drips—and also adds time due to repeated heating and extrusion steps. For users who print in multiple colors or materials, that means higher material costs, more plastic waste, and longer print times. It’s a workflow that’s harder to sustain, especially for frequent use.

That’s what led us to rethink the process. Instead of trying to make single-nozzle swaps more efficient, we designed a system that avoids them entirely. Our multi-toolhead setup keeps up to four printheads loaded at once and automatically swaps between them mid-print. No purging, no mess—just clean transitions and shorter print times. Each head stays perfectly aligned thanks to a smart locking system, and the compact design fits neatly into a desktop footprint. The result is a smoother, more sustainable way to print in full color or with different materials—without slowing you down or holding you back.

Design Goals

✅ Fast, precise printing

✅ Material-efficient with reduced failures

✅ Easy multi-color printing

✅ Home-friendly, clean aesthetic

Inspirations

A clean, modern product aesthetic defined by soft geometry, neutral tones, and intuitive interfaces. Each design emphasizes usability while maintaining a refined, timeless presence, blending seamlessly into contemporary living spaces.

Filament Routing Challenge

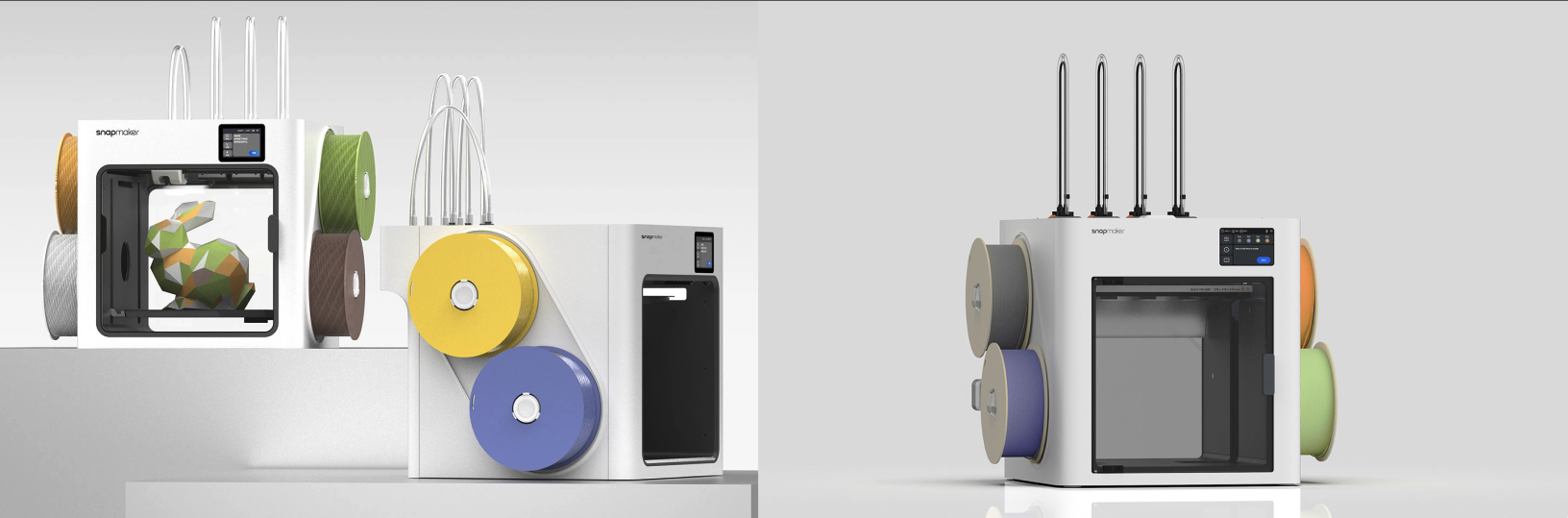

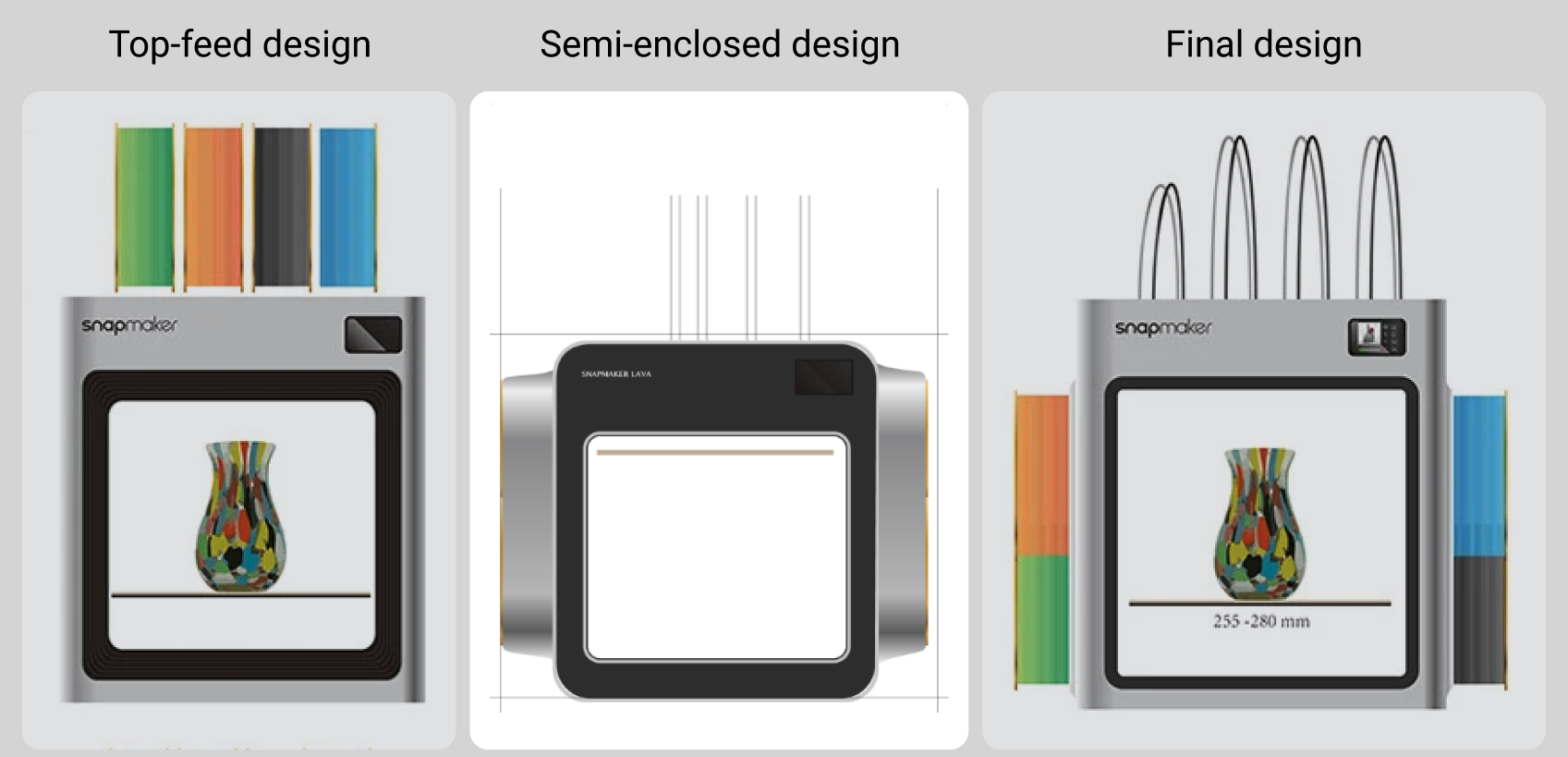

As shown in the picture, we explored both the top and side positions for holding spools and visualized them to facilitate discussion. We ultimately narrowed it down to the side position for a more holistic look. The top position is typically reserved for an AMS, and placing 4 kg of material on the back would risk tipping the machine over. Additionally, placing four spools on top would block the observation window.

Barebone Low-Cost Version

The barebone version focuses on core functionality while keeping production costs low, making advanced 3D printing more affordable. It has an open-top design with front and rear doors for easy access during maintenance and material changes. While not fully enclosed, it still offers partial coverage to improve safety and print stability where it matters most. This “half-open, half-enclosed” setup keeps key features like airflow control and shielding in place—delivering a clean, practical design that strikes a balance between performance and accessibility.

Fast Multi-Material Printing with an Auto-Swapping 4-Toolhead System

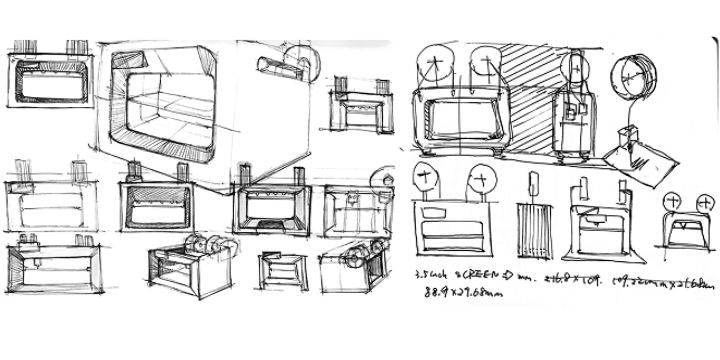

This project showcases the auto-swapping 4-toolhead system we designed for the Snapmaker U1. The goal was to allow seamless multi-material or multi-nozzle 3D printing—without the usual downtime or manual head swaps.

The system holds up to four toolheads at once, automatically swapping them mid-print using a compact, modular docking system. We focused on keeping the layout clean and serviceable, with built-in sensors to ensure each head is securely locked and accurately aligned.

Visually, we chose a warm industrial style that fits the Snapmaker ecosystem—functionally driven but approachable. Throughout this article, you’ll find development sketches, prototypes, and the final renders used in the design review and handoff.

Back the Snapmaker U1 here: https://www.kickstarter.com/projects/snapmaker/snapmaker-u1-color-3d-printer-5x-more-speed-5x-less-waste

Credits

Snapmaker Team

Lead Industrial Designer: You Li (Portfolio)

Product Manager: Zhongpeng Zhong

Together with Snapmaker Engineering & R&D Teams