PLA 3D Printing Temperature

When we talk about "PLA 3D printing temperature," we're not just referring to one setting, but rather a delicate balance of several key temperatures: the extruder nozzle, the print bed, and even the surrounding ambient environment. Read on to find the right balance of these temperatures.

PLA Extruder Temperature (Nozzle Temperature)

This is the temperature of the hot end of your 3D printer, specifically the nozzle where the PLA filament is melted and extruded. It's the most critical temperature in PLA printing.

190°C - 220°C is the most common range for standard PLA filaments. Some specialized PLA filaments, like silk or filled varieties, might print better at the higher end of this range or even slightly above (up to 230-240°C). *Officially tested data from Snapmaker.

Too Low: The PLA won't melt properly if the extruder temperature is too low. This can lead to:

- Clogging: The filament may not melt sufficiently and can jam in the nozzle.

- Poor Layer Adhesion: Layers may not bond together well, resulting in weak prints that can easily break apart.

- Skipping/Clicking Extruder: The extruder motor may struggle to push the filament through the nozzle, causing it to skip steps or make clicking noises.

- Under-Extrusion: Not enough filament is extruded, leading to gaps and weak structures in the print.

Too High: If the extruder temperature is too high, the PLA can become too runny and cause issues like:

- Stringing: Excess filament oozing out of the nozzle during travel moves, creating thin strands of plastic between parts of the print.

- Overhanging Issues: Soft, overly melted PLA may not cool and solidify quickly enough, leading to sagging or drooping overhangs.

- Heat Creep: Excess heat can travel up the hot end, softening the filament prematurely and potentially causing clogs.

- Warping: Although less common with PLA than ABS, excessive heat can still contribute to warping, especially on larger prints.

PLA Bed Temperature (Build Plate Temperature)

The print bed's temperature, where the initial layer of PLA is applied, is crucial. A heated bed temperature between 50°C and 65°C serves as an excellent starting point for PLA printing. *Officially tested data from Snapmaker.

While PLA can technically be printed without a heated bed, using one within this range greatly improves first layer adhesion and reduces warping.

Too Low: If the bed temperature is too low, the first layer of PLA may not stick to the build plate properly. This can lead to:

- Warping: The corners and edges of the print can lift off the bed as the PLA cools and contracts.

- Print Detachment: The entire print can detach from the bed mid-print, causing print failure.

- Poor First Layer: A weak or detached first layer comprises the foundation of the entire print.

Too High: While less problematic than too low, a bed temperature that is too high can also cause issues:

- Elephant's Foot: The first layer can become overly squished and spread out, creating a widened "foot" at the base of the print.

- Warping (in some cases): Excessive bed heat can contribute to warping in certain situations, although it's less common with PLA.

- Increased Cooling Time: The first layer may take longer to cool and solidify, potentially affecting print speed.

Ambient Temperature for PLA 3D Printing

While not directly set on your printer, the surrounding room temperature can play a role. Ideally, you want a stable and not excessively cold or hot environment. A comfortable room temperature is generally suitable.

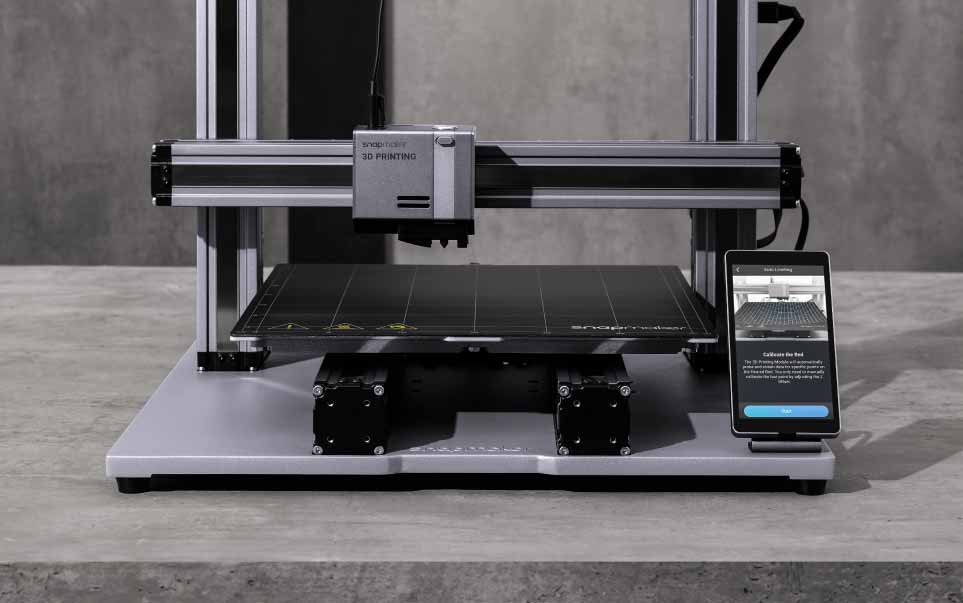

For maximum control, an enclosure creates a stable micro-climate by shielding the print from drafts and temperature swings. This significantly reduces warping on large PLA prints and improves layer adhesion. Accessories like the Snapmaker Enclosure, for example, are designed to provide this controlled environment for more consistent, high-quality results.

How Does Temperature Affect 3D Printing PLA

From the moment the filament enters the hot end until the final layer cools, temperature plays a crucial role in how PLA behaves, affecting everything from bed adhesion to the structural integrity of your print.

Like all thermoplastics, PLA contracts as it cools. This raises the question: how does bed temperature influence 3D printing in practice? A heated bed ensures that the initial layers of filament remain warm enough to adhere securely and resist warping throughout the printing process.

The glass transition temperature (Tg) for PLA is approximately 60°C, while nozzle temperatures typically range from 190°C to 220°C. At Tg, PLA becomes more flexible, but it has not yet reached a fully molten state. To achieve proper extrusion in 3D printing, PLA must be heated to a temperature that allows it to become sufficiently fluid to flow easily through the nozzle.

You can think of it like the transition from ice to water: Ice begins to soften and become slushy near 0°C (akin to Tg), but to obtain liquid water that flows freely, you need to reach temperatures above 0°C (similar to how nozzle temperatures must exceed Tg to melt PLA fully).

Once extruded, PLA needs to cool down and solidify quickly to retain its shape and form a solid structure.

Fine-Tuning Temperatures for PLA Variations

While the settings above are perfect for standard PLA, many exciting variations exist that offer unique finishes and properties. These specialized filaments often require slight adjustments to achieve the best results.

Silk PLA: For a Glossy, Smooth Finish

- General Characteristics: Silk PLA contains additives that enhance light reflection, giving it a characteristic high-gloss, "silky" appearance. These additives can make it slightly more prone to stringing.

- General Nozzle Temperature: Silk filaments typically require a slightly higher temperature to ensure the additives melt properly and the glossy finish is achieved. A common range is 205°C−230°C.

- Key Consideration: To maximize the sheen and minimize stringing, it's often best to use slightly slower print speeds (e.g., 30-60 mm/s) and well-tuned retraction settings.

Matte PLA: For a Non-Reflective, Professional Look

- General Characteristics: Matte PLA is formulated with micro-particles that diffuse light, resulting in a non-reflective finish that does an excellent job of hiding layer lines.

- General Nozzle Temperature: The ideal range is often slightly broader than standard PLA to accommodate different formulations, typically falling between 190°C−230°C.

- Key Consideration: The primary goal of this filament is its aesthetic finish. For instance, while a filament like Snapmaker's Matte PLA is engineered to perform well even at high speeds, you should always start with a test print to see what speed and temperature combination gives you the perfect finish.

High-Speed PLA: For Rapid Prototyping and Efficiency

- General Characteristics: High-Speed PLA is engineered with a higher Melt Flow Index (MFI), meaning it melts faster and flows more easily. This allows it to keep up with the demands of modern, high-speed printers without causing clogs or weak prints.

- General Nozzle Temperature: Critically, high-speed PLA requires higher temperatures as print speed increases.

- Standard Speeds (<100 mm/s): 190°C−210°C

- High Speeds (>100 mm/s): 210°C−230°C

- Key Consideration: To take full advantage of this filament, your printer needs to be capable of high speeds and acceleration, with sufficient part cooling. A product like Snapmaker's Snapspeed PLA is a good example, designed specifically for this purpose and aligning with these higher temperature recommendations for high-speed operation.

Key Takeaways

Precise temperature control is essential for successful PLA printing. Always be prepared to run a quick test print, like a temperature tower, to dial in the perfect settings for your specific filament and printer.