Milling Metal with the Snapmaker Artisan: What's Really Possible?

Acknowledging the Support

First of all, I want to thank Snapmaker for recognizing and appreciating the work I've shared with the community. I'm grateful for their support and the trust they've shown by encouraging me to share my experiences more broadly.

Just as importantly, a huge thank you to the Snapmaker community. Your openness, motivation, and constant curiosity have been a major driving force behind everything I've done. It's the encouraging responses, shared experiences, and collective desire to push boundaries that kept me motivated to go further than I initially thought possible.

From the Community, for the Community

My name is Michael Winkler, and like some of you reading this, I'm a fellow Snapmaker Artisan user. If you are not yet, hopefully, you will become one soon and be part of this great community 🙂. In my full-time role at WESTCAM Technologies, I'm surrounded by colleagues with a broad range of technical expertise. Our daily work involves evaluating machines, solving real production challenges, and optimizing systems. I quickly noticed how much overlap there is between my full-time work and the kind of methodical experimentation the Artisan rewards. This combination of persistence (some might call it stubbornness 🙂), my habit of documenting every step in detail (and also sometimes crazily overthinking it 🙂), has played a big role in reaching the level of results I can now share. I am satisfied with the results, but I'll let you be your own judge on the work I'm about to share here.

This journey remains a personal one — driven by curiosity, hands-on testing, and the desire to give back to a community that has inspired me time and time again. Whether you're curious about what's possible or already deep into CNC work, I believe sharing practical insights and real-world tests can help us all grow.

A Machine That Rewards the Right Approach

While the Artisan wasn't built to compete with industrial CNCs in sheer power or mass, that doesn't mean it can't produce impressive results — especially when paired with the right tools and a thoughtful approach. My goal is to help beginners take their first confident steps into metal milling and to offer seasoned machinists a look at what's possible when precision and strategy are put front and center on a compact platform.

Setting Up a Tool Library and Full Machine Simulation

To streamline my workflow and reduce setup errors, I am in the process of building a dedicated tool library in Autodesk Fusion for the Snapmaker Artisan. This allows me to preload accurate dimensions, flute lengths, and engagement parameters for each cutter I use — whether it's a single flute for aluminum or a chamfer mill for finishing. Having this library not only speeds up programming, it ensures consistency and helps avoid mistakes when generating toolpaths.

In addition, I managed to implement a handcrafted Artisan machine model into Fusion's simulation environment. This means I can now simulate tool motion with real fixture positions, visualize potential collisions, and verify reach and limits — all before ever touching the machine. It adds an extra layer of confidence, especially when running operations close to the machine's working envelope or using custom fixtures.

On top of that, I've also adapted the post-processor I use in Fusion. One of the improvements I noticed after this change was better Z-consistency across multi-pass operations and larger surfaces. However, I have to admit that I'm not fully convinced yet — it's possible that my positive impression was influenced by other factors or even just subjective perception. While some test results showed measurable differences, I haven't fully understood the underlying mechanism. It might be that I'm missing a detail in how the machine executes motion or interprets the G-code. Still, it's an interesting observation that I'll continue to investigate as I refine both my workflow and understanding.

Sometimes, subtle tweaks do lead to real-world improvements — and sometimes, they reveal how complex this whole process really is.

Dry Milling Aluminum? Yes, and With Great Results

This isn't about flooding your workspace with coolant or loading industrial-grade vises. I wanted to test whether aluminum could be milled effectively in dry conditions — and the answer is yes. With the correct workflow and attention to detail, I was able to achieve clean, consistent results without compromising the tool or the machine.

Based on my experience, the Artisan is capable of working with soft metals like aluminum and brass. Everything I share here is focused specifically on aluminum — and I would not recommend attempting to machine harder metals such as steel on this platform.

It takes time. And there's a reason for that. Before sharing any specific parameters, I want to be confident that they're not only effective but also safe — for your machine and for your peace of mind. Every step I document is part of making sure that what I pass on is something I'd trust myself to run.

The Right Tool Makes All the Difference

This is where everything starts. Early tests showed limited performance — until I switched to a tool designed specifically for dry aluminum milling. The difference was night and day. The latest tool I've tested — a professional-grade cutter designed for dry aluminum machining — has made a significant difference: visibly better surface quality, deeper engagement without chatter, and more reliable operation overall. Tool geometry, coating, and overall quality play a critical role. While inexpensive cutters might work for quick trials, it's often the higher-quality tools that reveal what the Artisan is truly capable of.

I was fortunate that a highly advanced tool manufacturer — one specializing in dry cutting aluminum — happened to be located nearby. What surprised me even more was the genuine interest they showed in my project. After a brief phone call, one of their experts insisted on visiting me at home to discuss tool selection in detail. I genuinely didn't expect this level of personal interest — especially from an expert in the B2B world, where time and attention are usually reserved for large-scale industrial clients. The fact that they took the time and made the effort to support a small hobbyist project like mine is something I truly admire. It stood out as a gesture of curiosity and support that made a lasting impression. That conversation helped me understand just how much impact the right cutter can have on performance and deepened my appreciation for what high-end tooling really enables on a compact machine like the Artisan. Suddenly, I wasn't fighting against chatter or watching the spindle struggle. The cuts were clean, chips were consistent, and surfaces came out with a quality I didn't expect from a desktop setup.

Optimizing CAM Strategies for a Desktop Machine

Trying to copy industrial workflows doesn't work here. Instead of forcing aggressive feeds or bulky strategies designed for heavy gantries and kilowatt spindles, I focused on refining CAM strategies tailored specifically for the Artisan.

This meant selecting machining strategies that would engage the tool with the right balance of radial and axial load, while avoiding sudden accelerations. I found success with constant load toolpaths, spiral roughing, and radial step-downs that matched the machine's rigidity and torque envelope. Entry and exit moves were always treated with extra care — not just for surface finish, but to preserve tool life and machine health.

The Artisan rewards you for restraint. I started seeing the best results not by pushing it harder, but by listening to its limitations — and creating motion patterns that avoided sudden torque spikes or unnecessary movements.

Testing Geometries and Tolerances

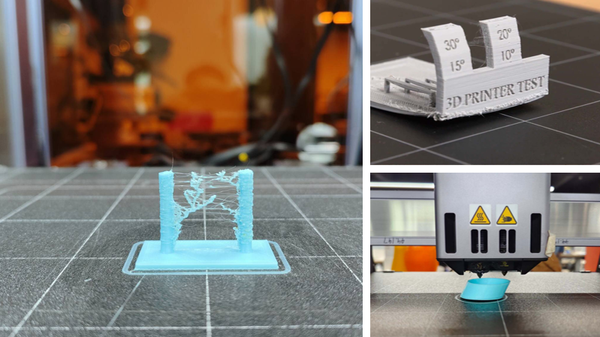

To validate my approach, I milled test pieces with various geometries:

- Flat-bottomed pockets

- Protruding cylinders

- Small chamfers and mating faces

- Organically shaped object (even though early focus now is set for technical parts, I did it as a bonus and a heads-up for myself on where the journey could lead me)

These tests helped me identify tool deflection limits, positional drift, and how different geometries affect finish quality. I also used them to measure how accurately the machine held tolerances after several hours of operation.

One particularly helpful exercise was repeating the same geometry over time and measuring the dimensional drift. If the Z-axis lost steps or the spindle deflected, it would show up — and that let me refine both strategy and machine setup.

Smart Entry Techniques

Material entry is one of the most overlooked, yet critical, aspects of machining — especially on desktop systems. On the Artisan, it's essential to use entry moves that are gentle, well-controlled, and adapted to the specific geometry and cutter.

I now focus on selective and smart entry techniques that avoid shock loads and unnecessary tool stress. This includes the use of gradual ramp-in angles, spiral entry where space allows, and minimizing direct plunges unless absolutely necessary. By tuning these entry strategies to each tool and application, I've been able to extend tool life and maintain better dimensional stability throughout the job. On a machine like this, proper entry isn't optional — it's essential.

Especially when using dry machining and compact tools, plunging directly into a pocket can be a death sentence for a sharp end mill. With smooth ramp-in motions, I gained the needed consistency.

Cooling vs. Dry Milling: What I Learned

One question I get a lot is, "Why not just use cooling?" The truth is, I tested both. While cooling definitely has its benefits, the complexity it adds — mist systems, chip control, mess — isn't always worth it for small-scale runs. This knowledge I took from one of my previous projects — a heavy 6-axis robot that I had the fortune to acquire and get back to life. I did not want to use coolant on the Artisan, worried not only about the mess but also about the machine itself.

So my approaches were without coolant.

Instead, I focused on chip evacuation, entry angle, and coated tools. I may eventually integrate a vortex cooler or use directed air, but even without it, I was able to reach a high level of performance.

That said, thermal control is still essential. I regularly paid attention to heat buildup — not with high-end sensors, but by observing chip color, machine sound, and tool behavior.

In some tests, I carefully touched the non-cutting part of the tool after the operation to get a rough sense of temperature. It was a conscious decision and done with care — but let me be clear: this is not recommended. Even indirect contact can carry risks, and safer methods (like timed pauses or non-contact temperature tools) should be preferred.

But no worries — you don't have to take that risk. That's what you have me for 🙂

Dealing with the Machine's Mechanical Constraints

The Artisan has its limits — let's not pretend otherwise. Spindle torque, axis stability, and even gantry rigidity all influence what's possible. But acknowledging these constraints allowed me to work around them, not be surprised by them.

For example, I avoided large sudden Z plunges, minimized axial cutting pressure, and used strategies that minimized lateral load. These mechanical realities became part of the toolpath design, not a limitation I ignored.

By respecting what the Artisan is — a precise, compact system — I've been able to get results that consistently surprise even experienced machinists. I'm especially thankful to the experts who've privately reached out, shared their backgrounds, and sparked new ideas through thoughtful conversation.

High-End Results from a Compact Machine

I've had experienced CNC programmers tell me they were surprised when they saw the finish and precision of the parts. I'm not going to lie — that felt pretty good 🙂. But more than personal encouragement, I see this kind of feedback as a sign of what's possible. And maybe, just maybe, it sparks something in you — the motivation to become the next CNC enthusiast, builder, or experimenter. If my content helps you take that first step or see new potential in the Artisan, then I book the hours I've spent writing this article as a success.

The Artisan's motion system is accurate enough to achieve sharp edges, consistent flatness, and repeatable dimensions — if you build your strategy around what it can actually do. It won't match a heavy vertical machining center in raw power, but it will impress when programmed right.

One of the earlier parts I made had such clean finishing steps that you could run your fingernail over the edge and feel the precision. That's when I realized: it's not about raw horsepower — it's about mechanical sympathy and smart planning.

Accessible for Beginners, Powerful for Experts

If you're just starting out, this might seem overwhelming — but I'd like to guide you through this, one step at a time. My goal is to break it down step by step, showing you what's possible in a way that feels approachable, achievable, and safe. You don't need to know everything to begin. With the right mindset and a bit of guidance, you'll build your confidence along the way.

And if you're a seasoned machinist — this might feel like a step back in size, but a step forward in challenge. It's a chance to rethink the fundamentals: precision, vibration control, and tool behavior, all within the limits of a tightly constrained desktop system.

Together, we'll explore how something as simple as tuning a single flute in aluminum can reveal insights that scale well beyond this machine. Every detail matters — and I'm here to explore those details with you.

Why I Chose Fusion

I've tested various CAM tools over time, including some powerful open-source solutions. Each had its strengths — and I hear the voices and wishes from the community for more focus on open-source CAM programs. I don't categorically exclude them. In fact, they might become part of what I cover in the future.

But as an enthusiast who also works full-time in a sometimes demanding job that occasionally takes me abroad for longer periods, I have to be selective with where I invest my limited time. Right now, Fusion gives me the best overall foundation — both for experimentation and for sharing practical, structured content that can help others.

For beginners, it offers a user-friendly interface without being oversimplified. And for those who want to go deeper, it provides:

- Accurate simulation with real tool and stock geometry

- Full-machine simulation when you build a custom setup

- A centralized and shareable tool library system

- A broad range of milling strategies with powerful tuning options

The combination of these features makes it easier to stay consistent, troubleshoot issues early, and learn faster from your own tests. Fusion didn't just help me program parts — it helped me understand the process better at every step.

What's Next?

This article marks just the beginning. I'm genuinely excited — maybe even a bit hungry 😄 — to continue sharing what I learn in future posts — including upcoming entries here in the Snapmaker Academy.

I'll walk you through real toolpaths, feed strategies, and test geometries. My aim is to give you the full picture: what worked, what failed, and how to think about CNC work in a structured, practical way.

You can expect:

- Step-by-step walkthroughs of test cuts

- Parameter ranges and the logic behind them

- Photos and videos of surface finish and tool performance

- Honest thoughts on limitations and how to deal with them

- How I build and use a custom Fusion tool library

- How to implement full machine simulation — improving confidence and approachability for beginners but also veterans and preventing costly errors

I also want to express my appreciation to Snapmaker for their openness and support. It means a lot to me that a company so committed to empowering makers takes interest in the work coming from within its own community. That kind of recognition encourages creators like me to keep pushing forward and sharing what we learn — and it ultimately strengthens the entire ecosystem of exploration and innovation around the Artisan.

Equally important: I want to shape this journey together with the community. Your questions, ideas, and feedback will directly influence what I explore next. If there's something unclear, challenging, or worth diving into deeper — let me know. I am trying to stay as active as possible in the Facebook group "Snapmaker Artisan Owners." I'm here to learn too, and together we'll uncover just how far we can take this machine.

And to those with more experience — I know there are bigger fish out there. I don't claim to have all the answers. What I share here is the result of what I've tested, observed, and refined on this specific machine. If you spot something I've overlooked or have a different perspective, I genuinely welcome it. Thoughtful feedback and discussion are not only helpful — they're essential for all of us to keep learning and improving.

Thanks for sticking with me to the end — I genuinely appreciate it. If this sparked even a small bit of curiosity, motivation, or inspiration, then I already count it as time well spent.

And now, if you'll excuse me — I should probably get back to making chips. 🙂

— Michael Winkler, your fellow Snapmaker Artisan user