What Materials Cannot Be Cut on a Laser Cutter

Laser cutting has a variety of beneficial uses, from creating ornate designs to industrial manufacturing. But before entering this extraordinary realm, you're going to want to know: What materials cannot be cut with a laser cutter? There are some downright dangerous materials. Setting clear expectations is helpful because we know the limitations.

Instead of just giving you a list of "don'ts," we'll explore why certain materials don't play nice with laser cutters. Understanding these principles will help you choose safer solutions and better project alternatives.

Materials That Are Not Suitable for Laser Cutting (With Diode Lasers)

If you're using a consumer-grade diode laser cutter, this guide is specifically for you.

Pro tip: While all diode lasers are semiconductor lasers, not all semiconductor lasers are simple diodes. Think of "semiconductor laser" as a family name, with diode lasers being just one branch of that family - typically the compact, lower-power devices you'll find in consumer machines.

Flammable Materials

Avoid using flammable and explosive materials to prevent fire risks.

- Polypropylene Foam: Highly flammable and can catch fire while cutting.

- Coated Carbon Fiber: The resin coating can give off toxic fumes, and cutting poses a significant fire risk.

- Oily or Resinous Wood: Pine, cedar, or teak woods have a high resin or oil content and can ignite or char excessively. Use untreated hardwoods like maple or birch.

Reflective Metals

Avoid highly reflective materials like mirror-finished aluminum, brass, and copper when using diode lasers. These materials reflect most of the diode laser beam's energy, making cutting extremely difficult. If necessary, use laser absorption coatings on these reflective materials to convert reflected light into heat and minimize safety risks.

- Mirror-finished Aluminum, Brass, and Copper: They reflect the laser beam, and hinder cutting ability. While specialized fiber lasers are designed for metal cutting, diode lasers are not. Use materials with non-reflective coatings.

Materials with Toxic Emissions

Carefully evaluate whether the material will produce toxic and harmful fumes during laser processing, and ensure that your air purification system can effectively filter it.

- Chlorinated Plastics (e.g., PVC and Vinyl): Cutting PVC releases chlorine gas, which is toxic to humans and can corrode the components of the laser cutter.

- ABS Plastic: It emits cyanide fumes when lasered. And it usually comes with melting results rather than a clean cut. Use acrylic instead.

- Chromium-tanned Leather: Chromium-tanned leather releases toxic chromium oxide fumes during laser cutting. Use vegetable-tanned leather instead.

- Certain types of Polycarbonate (PC): While some polycarbonates are laser-safe, others contain additives that can release toxic fumes when heated.

- Fiberglass: It contains both glass and resin, which can emit toxic fumes and harm the machine. Consider switching to laser compatible resins or glass without embedded fibers.

- Polystyrene Foam: It will burn quickly, give off toxic smoke, and catch fire easily. Make use of specially designed laser-safe foams.

Thickness of Materials

As a rule of thumb, materials thicker than 0.25 inch (6mm) begin to pose problems for most consumer diode lasers, notably denser materials, such as hardwoods. Your laser's power and material density may cause this to vary. It is also tricky to cut fragile materials cleanly.

Consult your laser cutter's specifications for recommended material thicknesses.

Common Laser Cutting Materials

Selection Principles

- Material Safety: Safety is paramount. Avoid materials that are flammable or release toxic fumes.

- Machine Capability: Consider the laser wavelength and laser power.

Recommending reading: Principles for Material Selection

For clarity, here are some common materials that can typically be cut with a laser cutter, especially on consumer-grade machines: (Officially tested materials with Snapmaker machines)

- Wood (basswood, paulownia, pinewood, beech, walnut, bamboo, MDF)

- Leather (vegetable-tanned leather, suede)

- Fabrics (cotton fabric, canvas)

- Laser-safe plastics

- Cardboard (corrugated fiberboard, A4 white paper)

- Non-transparent acrylic (blue excluded)

- Stainless Steel (0.1mm)

Note: Compatible materials vary according to the laser cutter's power. Always check your specific laser cutter's specifications.

Laser Cutting vs. Laser Engraving

The cutting or engraving method plays a part in what materials can be used with a laser.

- Laser Cutting: This process uses a laser beam to cut through the material. It requires higher power settings to pass through the material thoroughly. So it works best with thicker or denser materials like wood or acrylic.

- Laser Engraving: This process uses a lower-power laser to etch or mark the material's surface without cutting through. It's suitable for a broader range of materials. It is often used for decorative patterns, textures, or logos on various surfaces.

Laser Cutting with Safety and Creative Combinations

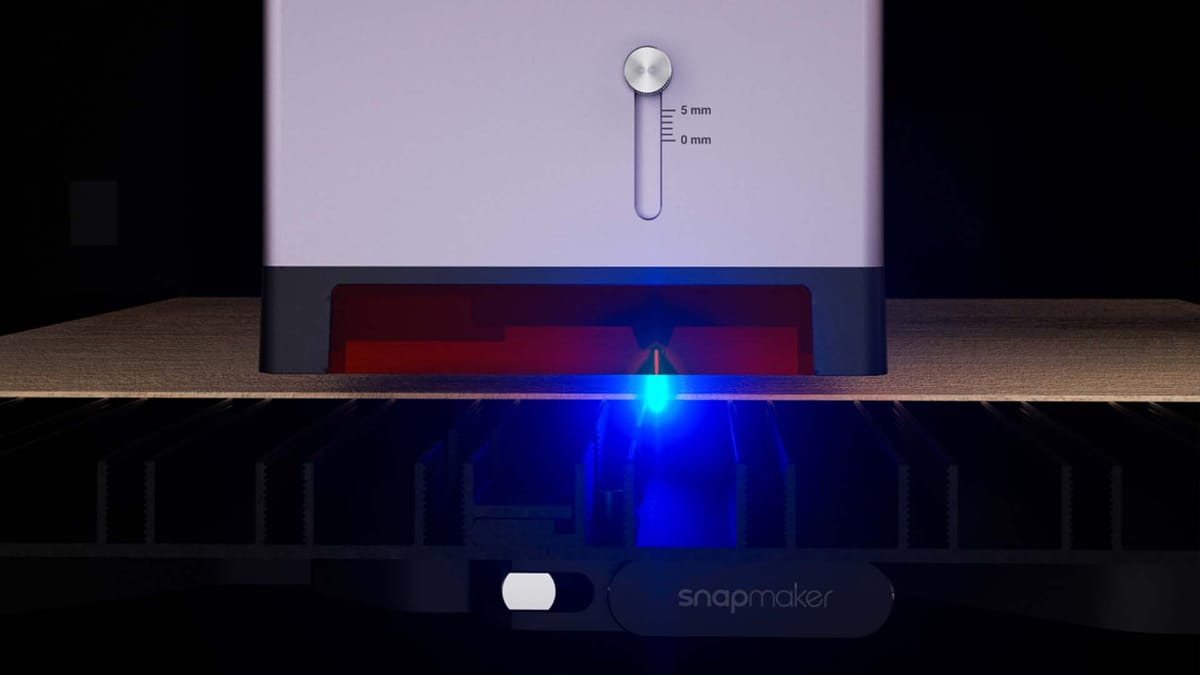

- Safety: Always wear appropriate laser safety goggles, work in a well-ventilated area, and follow the manufacturer's guidelines. Snapmaker Ray has brown acrylic enclosure panels and dust isolation settings, ensuring your safety.

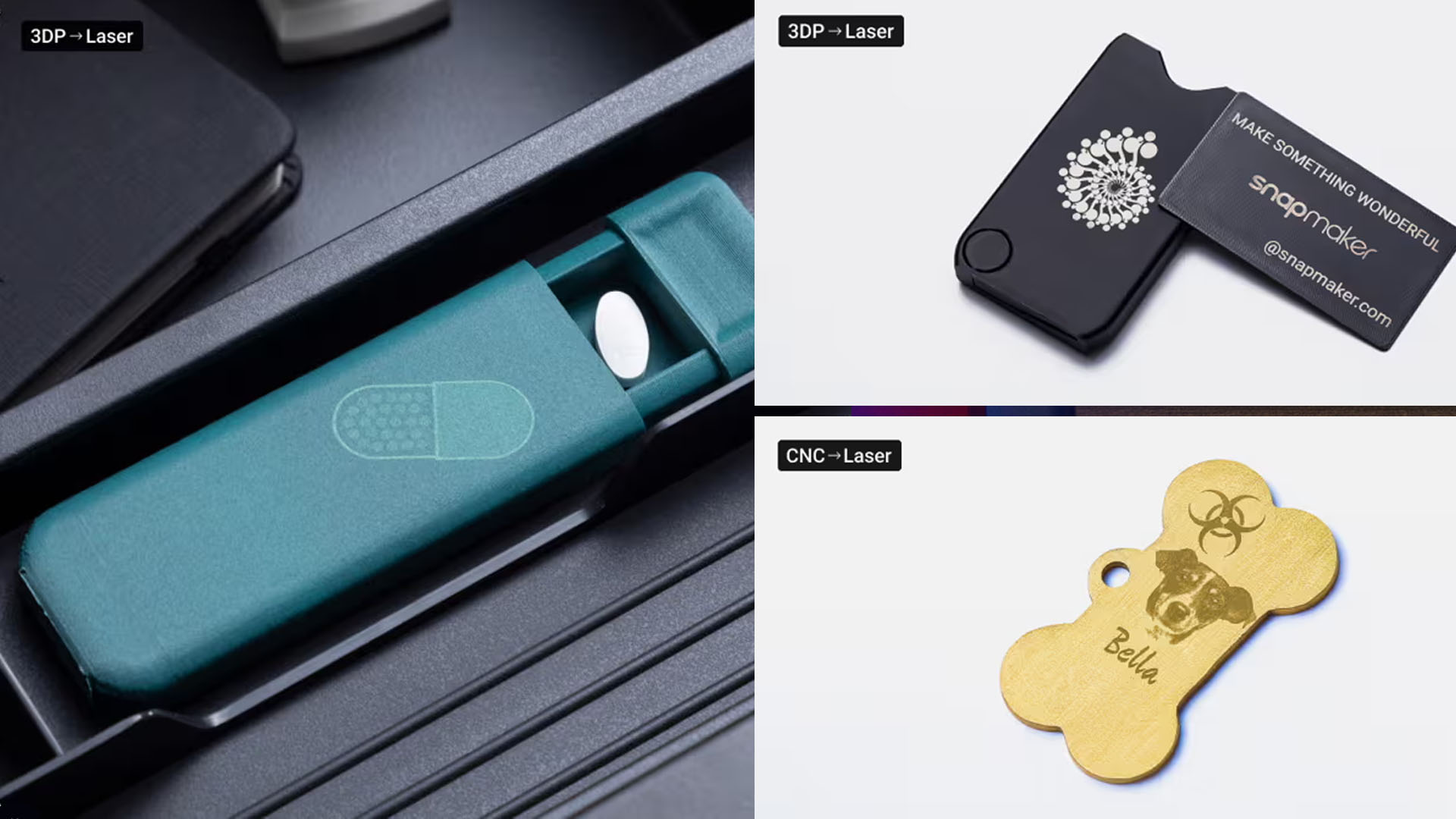

- Creative Combo: Combining laser cutting with techniques like 3D printing or CNC carving can open up exciting possibilities. Here is a mini electronic musical instrument made with 3 techniques.

Takeaways

Knowing what you can cut is as important as knowing what not to cut. When in doubt:

- Go through your machine's specifications

- Research material composition

- Test small samples first

- Ensure proper ventilation

- Keep safety equipment handy