How Much Electricity Does a 3D Printer Use? (A Detailed Cost Breakdown)

If you're considering buying your first 3D printer, it ’s natural to wonder about the hidden costs. You've factored in the price of the machine and the filament, but what about the electricity bill? It's a common concern, especially when you see large power supplies and hear about print jobs that can last for days. This article will give you a clear, data-backed answer and show you that the cost is much lower than you might think, helping you decide if a 3D printer is worth it.

The short answer is this: for most consumer 3D printers, the operational cost is typically between $0.05 and $0.15 per hour during a print. It's a surprisingly small number, and we're about to break down exactly why.

Understanding 3D Printer Power Consumption

A 3D printer's power consumption isn't a single, constant number. It's a dynamic process with a high peak at the beginning of a print, followed by a much lower average power draw for the remainder of the job.

Average Power Draw During a Print

The type of printer you use is the biggest factor. Fused Deposition Modeling (FDM) printers, which melt plastic filament, have a different energy profile than resin (SLA/LCD) printers, which use UV light to cure liquid resin.

- FDM Printers: These are the most common type of printer for hobbyists. After an initial heating peak that can draw 300W or more, a versatile FDM printer will settle into an average consumption of 100-150 watts while printing.

- Resin Printers: These machines don't have a high-power heated bed, so their energy use is much lower and more consistent, typically in the 30-60 watt range.

Translating Watts into a Real-World Cost

To figure out what this means for your wallet, you can use a simple formula. All you need to know is your printer's average wattage, the length of your print, and the rate your utility company charges per kilowatt-hour (kWh), which you can find on your bill.

(Average Wattage / 1,000) × Print Time (Hours) × Your Rate ($/kWh) = Total Print Cost

For example, let's calculate the cost of a 10-hour print on a machine averaging 120W, using the recent U.S. national average electricity rate of about $0.20/kWh:

(120W / 1,000) × 10 hours × $0.20/kWh = $0.24

That’s less than a quarter for a 10-hour job.

What Parts of Your 3D Printer Use the Most Electricity?

The total power rating of a machine isn't what it consumes continuously. That power is directed to different components as needed, with two parts doing most of the heavy lifting.

The #1 Consumer: The Heated Bed

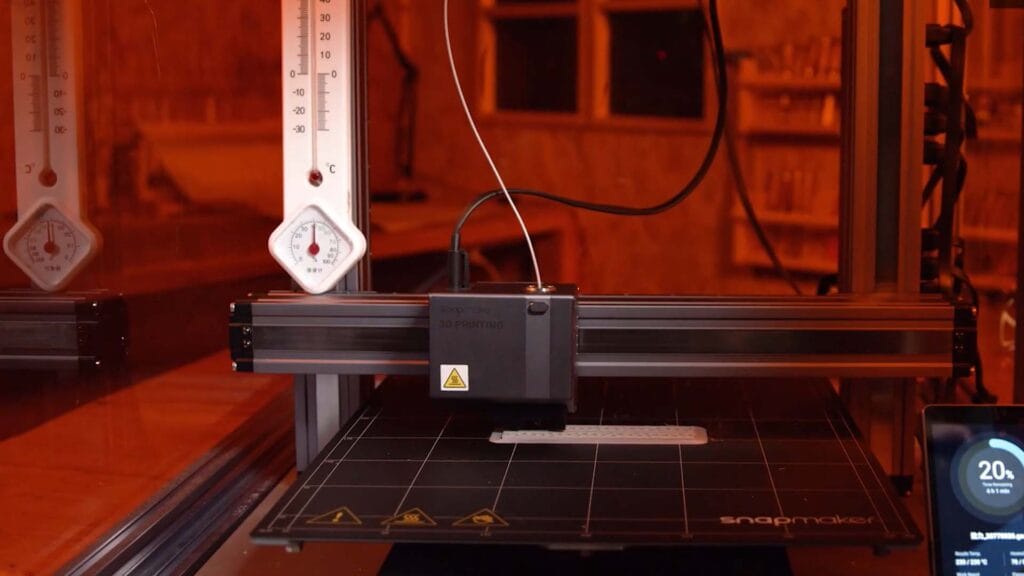

The heated bed is unequivocally the single largest power consumer in an FDM printer. Its job is to keep the print's first layer warm to ensure it sticks properly and doesn't warp. Heating a large build plate, like the spacious 400 × 400 × 400 mm work area on the Snapmaker Artisan, requires a robust power supply to get it to temperature quickly. Once it's hot, however, it simply cycles on and off to efficiently maintain that temperature.

The #2 Consumer: The Hotend

The hot end is the part of the toolhead that melts the plastic filament right before it's placed on the model. Modern toolheads, like the Dual Extrusion module for the Artisan, are highly efficient. While they can heat up quickly, their overall consumption is significantly less than the heated bed's.

Industrial-Grade Motors, Electronics, and Touchscreen

The rest of the printer's components—the high-precision motors that drive the industrial-grade linear rails, the powerful mainboard, and the large 7" touchscreen—consume a relatively small and stable amount of energy throughout the print.

How to Calculate Your 3D Printer's Exact Energy Cost

While general estimates are helpful, you can find the exact usage of your specific machine in two ways.

The Most Accurate Method: Using an Electricity Usage Monitor

The gold standard for accuracy is a plug-in energy meter. You simply plug the monitor into the wall and plug your printer into the monitor. Run a typical multi-hour print, and the device will tell you exactly how many kilowatt-hours your printer consumed. It's the best way to get a true measure of your real-world consumption.

The Estimation Method: Understanding Your Power Supply

You can also look at the power supply unit (PSU) on your printer. It’s critical to understand that the rating indicates the machine's maximum potential power, not its average use. This power is necessary to handle demanding jobs, like quickly heating the large bed or running the 200W CNC module, but the average power draw for 3D printing is only a small fraction of this maximum.

Key Factors That Optimize Power Consumption

You can take several steps to make your 3D printing even more efficient.

Print Temperature and Materials

High-temperature materials like ABS require more energy to maintain higher bed and nozzle temperatures compared to a material like PLA, which prints at lower temperatures.

The Benefit of an Enclosure

The single most effective way to reduce energy consumption is to use an enclosure. The Enclosure for Snapmaker machines serves a dual purpose. First, it provides critical Laser Class 1 Safety when using the laser module. Second, it traps waste heat from the printer. This creates a stable, warm environment that dramatically reduces the energy the heated bed needs to stay warm, leading to more efficient printing and better print quality.

The Verdict: Are 3D Printers Expensive to Run?

After looking at the data, the answer is a definitive no. When you compare a 3D printer to other devices in your home, its energy use is modest.

Comparing a 3D Printer to Common Household Appliances

The average power draw of an FDM printer (100-150W) is similar to that of a modern TV or a high-end desktop computer. It's dwarfed by high-power appliances like a microwave (~1,200W) or a space heater (~1,500W). Running a space heater for just one hour consumes the same amount of energy as running your 3D printer for 10-15 hours.

The Real Costs: Calculating Filament vs. Electricity

Ultimately, the cost of filament is the primary recurring expense in 3D printing. The electricity used to turn that spool of plastic into a finished object is a very minor part of the equation. To plan your projects accurately, tools like the official Snapmaker Filament Calculator are invaluable for estimating your material costs, which will always be more significant than the electricity used to print.