From Just An Idea to A Gentlemen’s Orrery: Frans van Hoesel’s Snapmaker Journey

For over a year, I wandered around the house looking for something that could justify buying a 3D printer. A broken part, a missing bracket, some half-finished project—surely, I could find a reason. But nothing ever seemed quite good enough.

Still, about five years ago, I stumbled on Snapmaker 2.0 with its all-in-one promise and bought it—because, let’s be honest, when has needing something ever truly been the deciding factor?

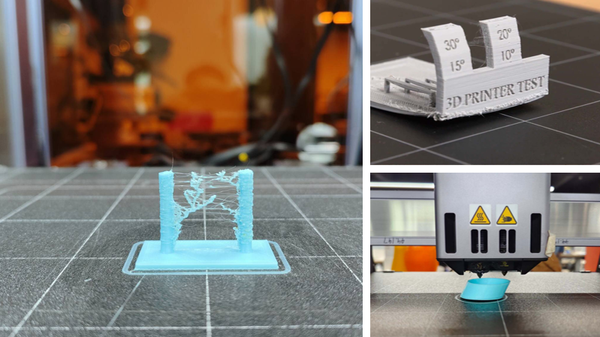

At first, I tried the included filament and got awful results—weak prints that weren’t worth keeping. The results were stringy and kind of sad. I almost gave up… until I randomly tried a different filament a few months later—and just like that, everything worked. Everything printed beautifully.

It took me another six months to fire up the laser, then another half a year before I gathered the nerve to use the CNC. I found it a bit intimidating, but once I got over that, I was hooked. Without the 3-in-1 setup, I doubt I’d have ever bought a standalone laser or CNC. But having them there, whispering "try me" from the corner of the shed? Game changer!

Since then, I’ve made quite a few things—some that I think turned out pretty well. "What I really enjoy is figuring out new ways to use the machine or inventing something entirely new.😉 "

For example, I came up with an idea—new mechanism for an orrery. Laser cutting and engraving was the key.

I also tried a 3D printed version. That one actually won the grand prize on Instructables.com.

In between, I carved Soapstone for the first time. That one somehow landed me a 40W laser in Snapmaker’s CNC Challenge in 2024.

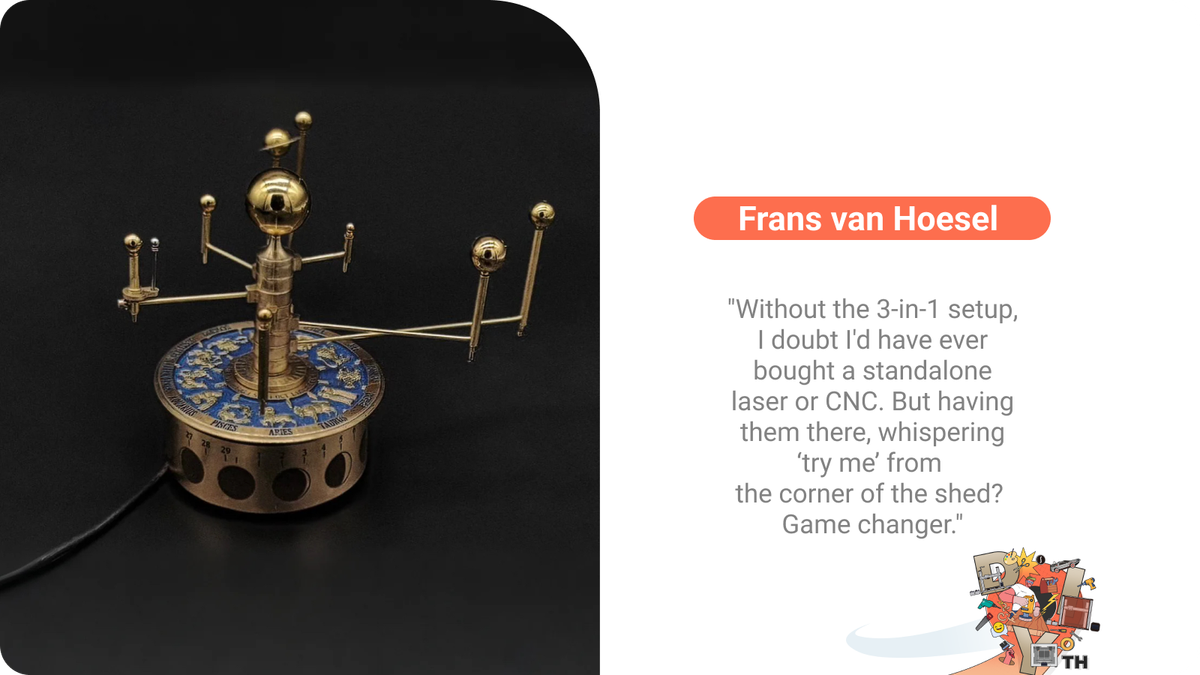

But I wanted to go bigger—a real showcase of everything the machine could do. A Gentleman’s Orrery is a bit of a wink to the Enlightenment era, when tools like orreries were considered the height of intellectual refinement. Back then, being a "gentleman" wasn’t just about wearing a cravat—it meant you dabbled in philosophy, appreciated the sciences, and probably had an orrery spinning slowly on a bookshelf next to your copy of Newton’s Principia. I designed it to look like a classic orrery, while working on a completely different principle. It’s mostly made from brass (because shiny brass = instant credibility).

I started with the 3D printer, using pink PLA to build the internal structure that holds a stepper motor, ESP32, motor controller, and touch sensor. A brass bridge holds and aligns the central column. The CNC handled most of the brass work, including gears and a zodiac disk. For the involute gears, I wrote (with the help of ChatGPT!) a Python program to generate the G-code to drive the CNC and rotary.

For the relief on the zodiac, I started with some pen drawings I found online. I used ChatGPT to convert them into smooth grayscale images, uploaded them to MakerWorld’s image-to-3D tool, imported the resulting 3D models into 3ds Max to flatten them to 1mm height, then exported them to Fusion 360 to generate G-code for Snapmaker.

I used the laser to engrave moon phases onto the housing.

And then—because I couldn’t resist—I carved a soapstone housing using the CNC with Snapmaker's Rotary Module. The brass design fits neatly inside. I honestly can’t decide which version I prefer, so I’ve kept both.

This project really shows what the Snapmaker can do when all three modules come together. By leveraging 3D printing for structural components, CNC carving for precise metal parts, and laser engraving for detailed artwork, I created a nice blend of technology and tradition – plus a pretty good excuse for finally buying that 3D printer.

— Frans van Hoesel