From Fridge Hinges to Hotel Fixtures: How a Snapmaker 2.0 Helped Me Build a Business From Home

When I first stumbled across the Snapmaker 2.0 on Facebook Marketplace, I didn’t know I was about to change the way I think about creating, repairing, and even running a business. I was just a guy who liked to tinker—but had no workshop, no formal experience, and definitely no idea how to use CAD software, slicers, or CNC routers. What I did have was curiosity—and a constant frustration with things I couldn't fix.

Take the travel cooler in my garage, for example. Its hinges were long broken, and the parts were discontinued. I scoured eBay, forums, parts warehouses—nothing. Eventually, like many others, I gave up and either bodged something ugly together or scrapped it entirely, adding to the growing mountain of waste that comes from products we can’t fix. That was before Snapmaker.

Discovering the Tool That Changed Everything

The ad was simple: a full Snapmaker 2.0 kit, already assembled, for sale by someone who didn't have enough time to figure it out. Six hours of driving later, it was mine.

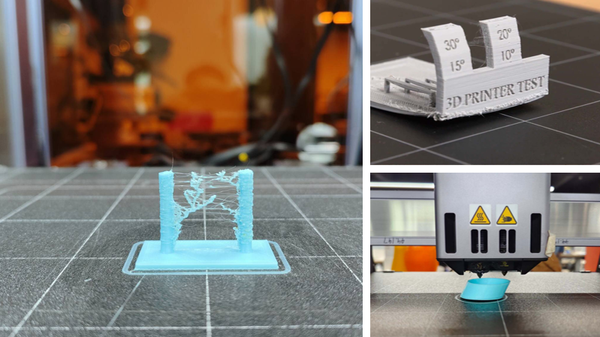

At first, I was just excited to see it move—the whir of the stepper motors made me feel like I was standing at the edge of something new. But reality hit fast. I had no idea what I was doing. No experience in CAD, laser software, or slicing tools. So I did what I always do: I read the manual—every word. I double-checked the assembly. And then I turned to the Snapmaker Academy and Snapmaker Community.

Those early projects—simple designs using the included software, Snapmaker Luban—gave me a foundation. But I knew I wanted more. I didn’t just want to use Snapmaker. I wanted to speak the language of real-world tools: Fusion 360 for design and CNC, Prusa Slicer for 3D printing, LightBurn for all my laser needs. And the only way to learn? Set a goal and chase it.

The Fridge Hinge That Started It All

That travel cooler? It became my first mission. I followed free online tutorials, designed the missing hinge in Fusion 360, and sliced it for printing in PrusaSlicer. My first print was a mess—wrong orientation—but I learned. A few iterations later, I had a working hinge. Later, I reprinted it in ASA for durability. It held up so well, and I was able to sell the fridge a year later, with spare hinges included!

That experience taught me two things:

- You don’t need to know everything to start.

- Iterations produce waste—it isn't always necessary. Design better, waste less.

From Problem Solver to Community Contributor

As I gained skills, I became more active in the Snapmaker community. That’s where I learned how others were modifying their machines to get more out of them. I started improving my own machine—using Snapmaker to upgrade itself. This journey led me to design my own Klicky Probe mod, helping other users save time with auto-leveling and allowing them to use print surfaces like Garolite. It was my first real product, designed from scratch and shared with the world.

Then Came the Dyson Mount—and the Light Fixture That Changed Everything

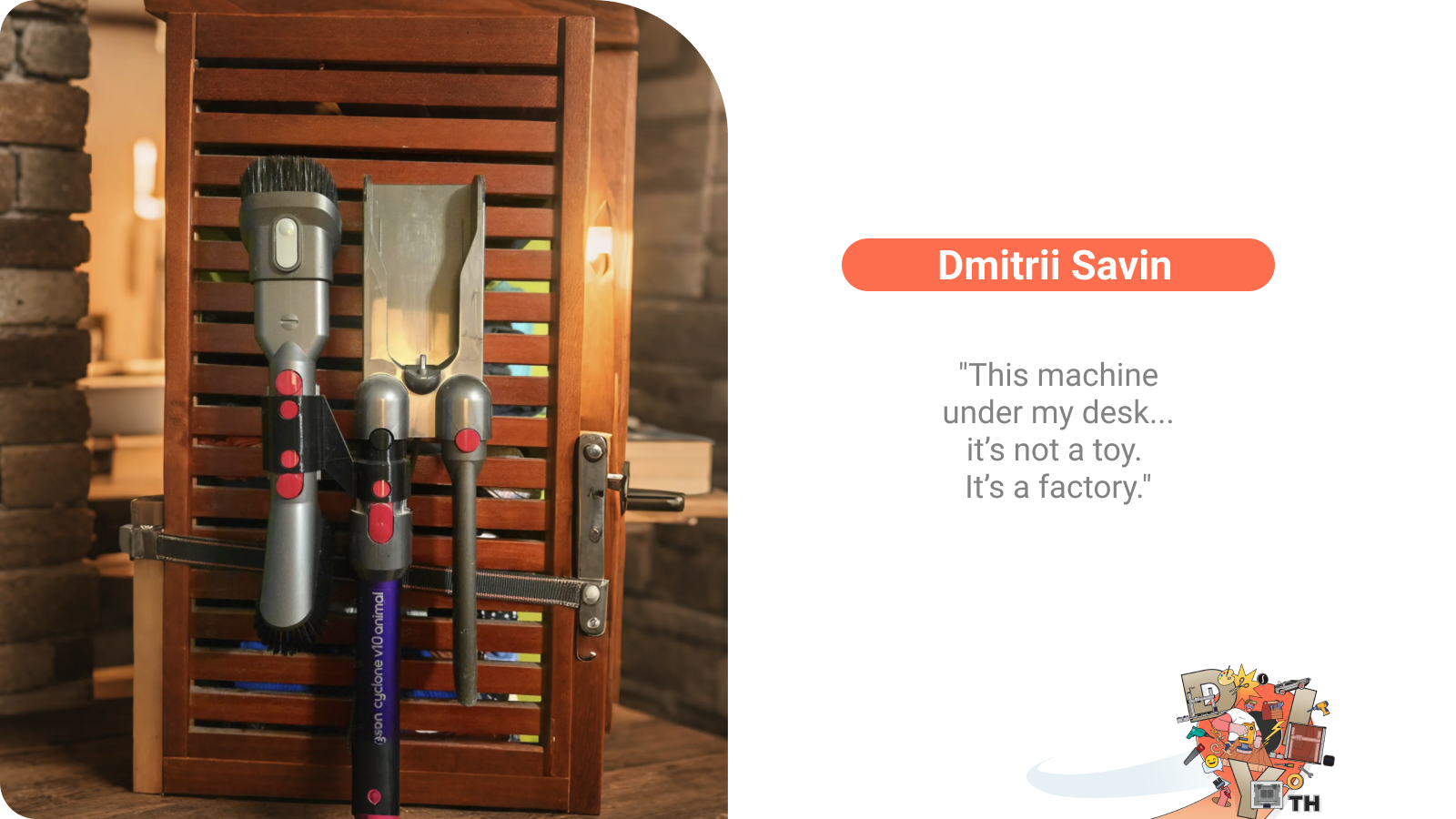

I wasn’t designing everything from scratch at first. One of my early “real-world wins” came from printing a vacuum accessory mount for my Dyson. Found online, printed locally, and suddenly all my attachments had a home. I showed it to my neighbor.

Then another. Before long, I was selling batches for friends and neighbors, thanks to the license @albrnick used to publish his creation.

"💡This machine under my desk... it’s not a toy. It’s a factory."

I started reaching out to local contractors—electricians, HVAC techs, plumbers—not to sell gadgets, but to offer solutions. I focused only on projects that wouldn’t end up in the landfill. Real, durable, functional parts. That decision helped me narrow my scope and speak the language of professionals.

And Then Came the Hotel Project

A local electrical contractor needed a fix—fast. A niche in a concrete wall in a hotel renovation project wasn’t sized correctly, and 200 light fixtures no longer fit. Their options? Pay for custom metal fittings (expensive), or buy all new lights (even worse). I offered a third way: custom brackets, printed to spec to fill the gap.

Three iterations later, the part was ready. It was field-tested and worked. They ordered 200 units.

With only one Snapmaker, I couldn’t meet the demand and the deadline—so I outsourced some of the production. The money I earned from that job? I reinvested. I bought more Snapmaker.

Why It Matters

Today, I run a small local manufacturing operation out of the warehouse I was able to rent, supporting contractors with custom parts, tools, and prototypes. But what I’ve gained isn’t just technical skill or a business—it’s the ability to really affect the world around me in a positive way.

Digital fabrication has changed how I think. With Snapmaker, I can iterate quickly, prototype new products, and even send designs to larger manufacturers for full-scale production. I’m no longer at the mercy of what’s available on shelves. I can make what I need—and help others do the same.

If you're reading this and thinking, “That sounds great, but I’m not smart or skilled enough to learn all that.” — Let me tell you something: Nobody is, at first.

But if you set a goal, carve out time, and stick with it—even a little bit every day—you’ll be amazed at what you can achieve.

— Dmitrii Savin