From Curiosity to Mastery: Renee's Snapmaker A350 Journey

In November 2020, the algorithm got me.

A Facebook ad came up in my feed for a sleek, cool-looking 3-in-1 machine called the Snapmaker 2.0 A350. I shared it on my timeline without much thought—just a "look at this!" moment. I was drawn to the CNC carving capabilities, having worked with specialty routers and a lathe in my woodworking past. The laser? Honestly, I didn't think I'd use it much. The 3D printer? Maybe for fun. But something about this machine stuck with me.

To my surprise, a few weeks later, I got a message: my parents had seen that post—and in an act of legendary gift-giving, they decided to surprise me with it for Christmas.

My dad, an engineer who once programmed CNC machines to build helicopter parts and who was a skilled carpenter, had spent his life encouraging his kids to tinker with tools and technology. This machine? It felt like his legacy wrapped in a modern shell—techy, tactile, and endlessly creative.

I got the message in late December: it was on its way.

It finally arrived in January 2021, during the tail end of COVID lockdowns, at a time when I wasn't working and desperately needed something creative to focus on.

That gift wasn't just timely—it was transformative.

Something to give me the ability to build, to learn, to make.

I spent hours assembling the machine, following the beautifully detailed manuals. My parents had also given me the enclosure, which let me set it up in my home office/studio space.

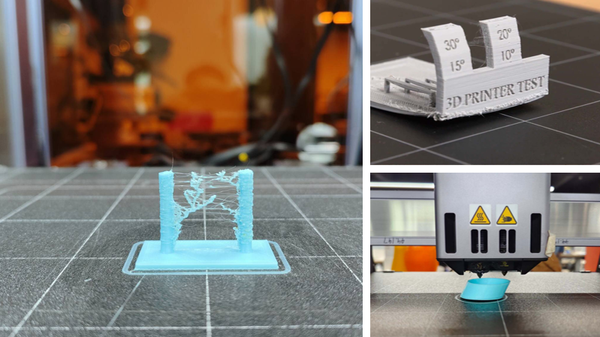

Once it was built, I installed Luban and tried the first sample project with the 3D printer. It was a failure—not because of the machine, but because of my lack of knowledge. So I tried again and made my first Benchy!

And I was instantly hooked.

For the next several weeks, I dove in headfirst—testing toolheads, swapping modules, and learning as I went.

The quick-swap kit hadn't come out yet, so the tool and bed changes were... character-building. But the learning curve wasn't the machine—it was me. I had big ideas, but I didn't yet know how to bring them to life.

The CNC module, my original draw, challenged me most. I didn't yet understand toolpaths (don't even talk to me about multiple toolpaths!), file prep, or how to get consistent results.

So I turned to the growing community—Facebook groups, Snapmaker forums, message boards.

I posted questions, shared my early projects, and got incredible feedback.

Step by step, my confidence and skills grew.

From small laser engravings and beginner CNC carvings, I started creating more advanced work—layered designs, 3D elements, intricate woodwork.

I began investing in every upgrade Snapmaker released:

- the 10W laser, then the 40W

- the rotary module

- the upgraded CNC head

- the quick-swap kit

Each addition opened new doors, and I walked through every one of them.

Although CNC initially drew me in, laser engraving became my passion.

I bought files on Etsy—some good and some bad—and learned about kerfs and how to get a tight-fit notch or tab-and-slot cut. How to adjust a design for different thicknesses of wood.

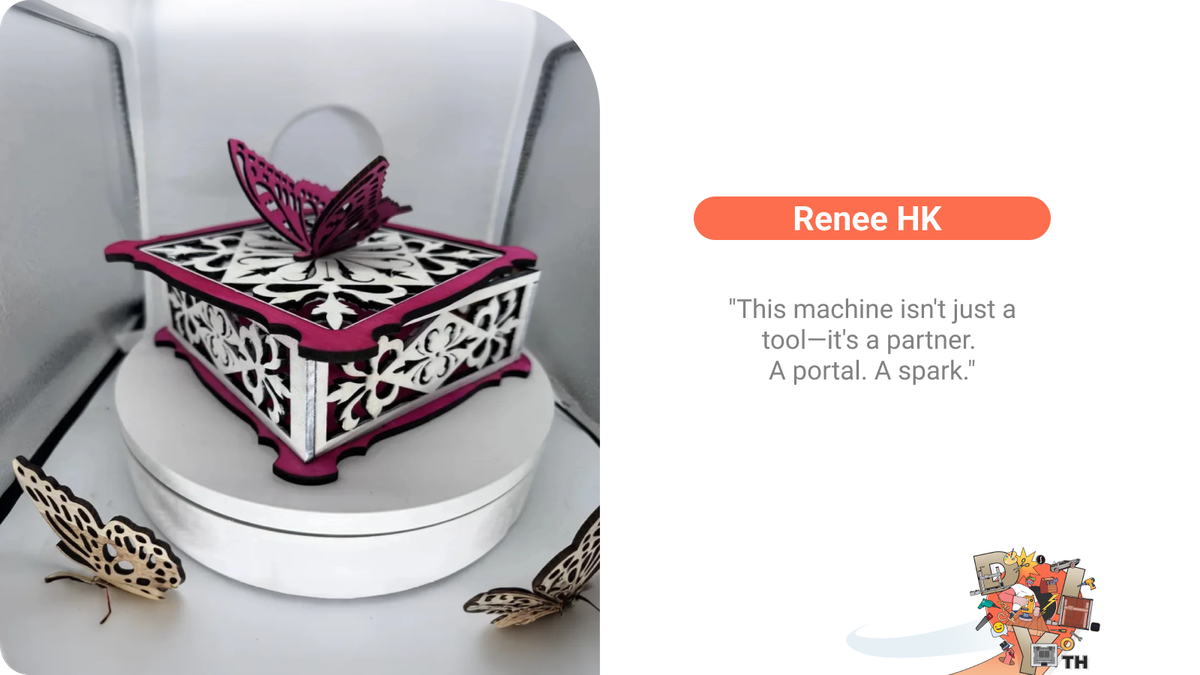

I now use LightBurn and design multi-layered gothic-inspired pieces that sometimes span 10 sheets or more of material, using both engraving and cutting in the same design.

I create custom altars, boxes, and shelves with my Snapmaker, combining technical precision with personal artistry. Every project is a mix of software, sawdust, and soul.

And I give back.

I stay active in the Snapmaker community, offering advice to new users, recommending external software like Carveco Maker, and sharing designs and tutorials.

I know what it's like to be new, excited, and overwhelmed—and this community made all the difference for me.

This machine isn't just a tool—it's a partner.

A portal.

A spark.

And the company itself? Snapmaker isn't just selling hardware. Their support staff is present, engaged, and deeply invested in user success.

When you buy a Snapmaker, you don't just get a machine.

You get a tribe.

So yes—thank you, Facebook algorithm.

Thank you, Mom and Dad.

And thank you, Snapmaker, for helping me carve, burn, and print my creativity into the world.

— Renee Haden-Knost