FDM 3D Printing Filaments 101

The FDM (Fused Deposition Modeling) is mainly used for 3D printing techniques. The reason for that is its strength, flexibility, and the fact that it is very simple to use, people produce very good prints with it. But the catch? You have to select the correct filament, as it obviously influences the quality of the print. So, which material should you choose?

In this guide, you will get the different 3d printer filament types and uses that are used widely and their respective applications, so this will help you to find the right filament. These will make your prints look even better and will help you to get to a completely new level of printing no matter if you are at the beginning or already a pro.

What Are FDM 3D Printing Filaments?

FDM 3D printing filaments are the plastic threads used for the construction of objects layer by layer. The filament material is fed into the 3D printer extruder, where it is melted down and then flows through the heated nozzle to create the 3D object. The filaments consist of many materials supplied on spools.

Why Filament Choice Matters

It is important to select the right filament as this will determine the level of smoothness and the strength of the print. PLA is bio-degradable, easy to work with, and suitable for a beginner for their first printer, but it cannot tolerate high temperatures well, is quite brittle and has a tendency to detach itself from the prints.

On the other hand, ABS is more durable and resistant to heat and shock, and thus is tougher but can only be printed at a relatively high temperature; moreover, it may have an unpleasant smell when used. Picking up the wrong filament may mess up your print.

Common FDM 3D Printing Filaments

Below are some of the most common 3D printer filament types. Each filament includes properties, pros/cons, hardware needs, and best uses.

PLA (Polylactic Acid)

- Properties: Eco-friendly, melts at 180-220°C.

- Pros: Easy to print, no heated bed required, low odor.

- Cons: Low strength, poor heat resistance (softens at ~60°C).

- Best Uses: Prototypes, decorative items.

A Quick Tip on PLA Variations: Thanks to its immense popularity, the PLA family has grown far beyond the standard formula. This innovation is great for makers, offering specialized versions tailored to specific needs. For projects demanding a professional, non-reflective surface that hides layer lines, Matte PLA is an excellent choice. For users focused on efficiency with modern, fast printers, High-Speed PLA is engineered to keep up with demanding speeds.

ASA (Acrylonitrile Styrene Acrylate)

- Properties: UV-resistant, melts at 240-260°C.

- Pros: Great for outdoor use.

- Cons: Odorous.

- Best Uses: Outdoor parts.

Carbon Fiber

- Properties: Lightweight, high strength.

- Pros: Rigid, strong.

- Cons: Abrasive, expensive.

- Best Uses: Aerospace parts.

PEEK (Polyether Ether Ketone)

- Properties: Ultra heat-resistant (340°C+).

- Pros: Chemically resistant.

- Cons: Costly, needs specialized gear.

- Best Uses: Medical, industrial parts.

Wood

- Properties: Wood-fiber blend, wood-like look.

- Pros: Aesthetic, sandable.

- Cons: Weak.

- Best Uses: Art pieces.

Metal

- Properties: Metal-powder infused.

- Pros: Metallic finish.

- Cons: Not functional, abrasive.

- Best Uses: Decorative items.

PVA & HIPS (Support Materials)

- Properties: PVA water-soluble, HIPS limonene-soluble.

- Pros: Easy support removal.

- Cons: Expensive, dual-extruder needed.

- Best Uses: Complex structure supports.

Technical Tips: Optimizing Filament Printing

Some types of 3D printer filament need special setups for printing. Here are some working tips that will help enhance your 3D printing experience.

- Fine tune your 3D printer settings. For instance, use a cooling fan and balance speed to prevent warping.

- For ABS, use a box, as it prints better in enclosed spaces. To smooth ABS, use acetone or sanding wood prints for a smooth and polished look.

- Use a tough nozzle, such as steel, for carbon fiber and a hot setup for high-temperature materials like PEEK.

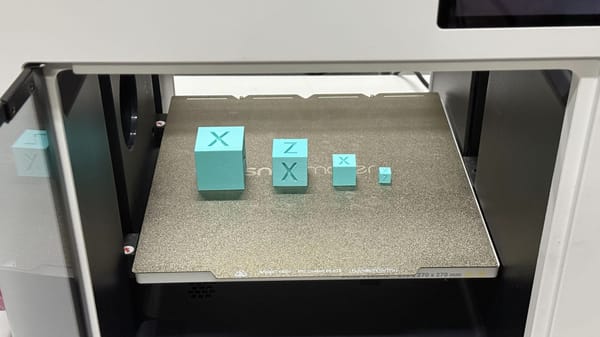

Besides filaments, choosing the right 3D printer becomes equally important. Consider the Snapmaker Artisan – an all-in-one 3D printer that works for 3D painting, CNC carving, and laser engraving. It has a huge work area of about 400mm x 400mm x 400mm, letting you do multiple prints at once.

The Snapmaker Artisan’s high-quality hardware, made of industrial-grade linear rails and quick-swap tool heads, allows you to switch between different functions easily. Its dual-extrusion setup and intuitive touchscreen offer ease of use and versatility.

How to Choose the Right Filament for Your Project

As a beginner 3D printer, how do you go about choosing a filament?

- For beginners, choose either PLA or PETG: they are both easy and relatively cheap to print.

- Functional parts: Strong and durable materials that should be used are ABS, Nylon, and PC, for example, for any part that serves a functional purpose.

- Flexible Needs: TPU and PP flex with no breaking, suitable for flexible projects.

- High-heat settings: PC PEEK and ASA are high temperature-resistant.

- Decorative: Wood or metal filaments are ideal to create unique textures.

- Complex designs: Use PVA or HIPS to create complex designs.

- Include a comparison table: strength, heat resistance, cost, etc.

Conclusion

The filaments used in 3D printing have limited options, but not so limited that you can't find what you need; hence, it is the most important thing to do. Choose the right one to suit your printing job. You will have to experiment with various filament materials before getting the one that fits your needs and wants the best.

We hope this blog helped you get an idea of different types of 3D filaments. If you have any questions or want to share your experiences with 3D filaments, comment below. Check out some filament links to find the best 3D filaments.