Enclosed vs. Open 3D Printer: A Practical Guide to Choosing the Right One

Choosing your first (or next) 3D printer can feel overwhelming, and one of the biggest points of confusion is the debate between an enclosed or an open-frame design. It’s frustrating to sift through technical jargon only to be left wondering if you’re about to invest in the wrong machine for your goals.

This guide will cut through the noise. We will provide a clear, practical framework that breaks down the choice into four simple factors. By the end, the debate will be settled, and you will know exactly which type of printer is the right choice for you.

The Fundamental Difference: It's All About Environmental Control

Before weighing the pros and cons, it's essential to understand the one core principle that separates these two types of printers: how they interact with their environment.

How Open-Frame Printers Use Airflow

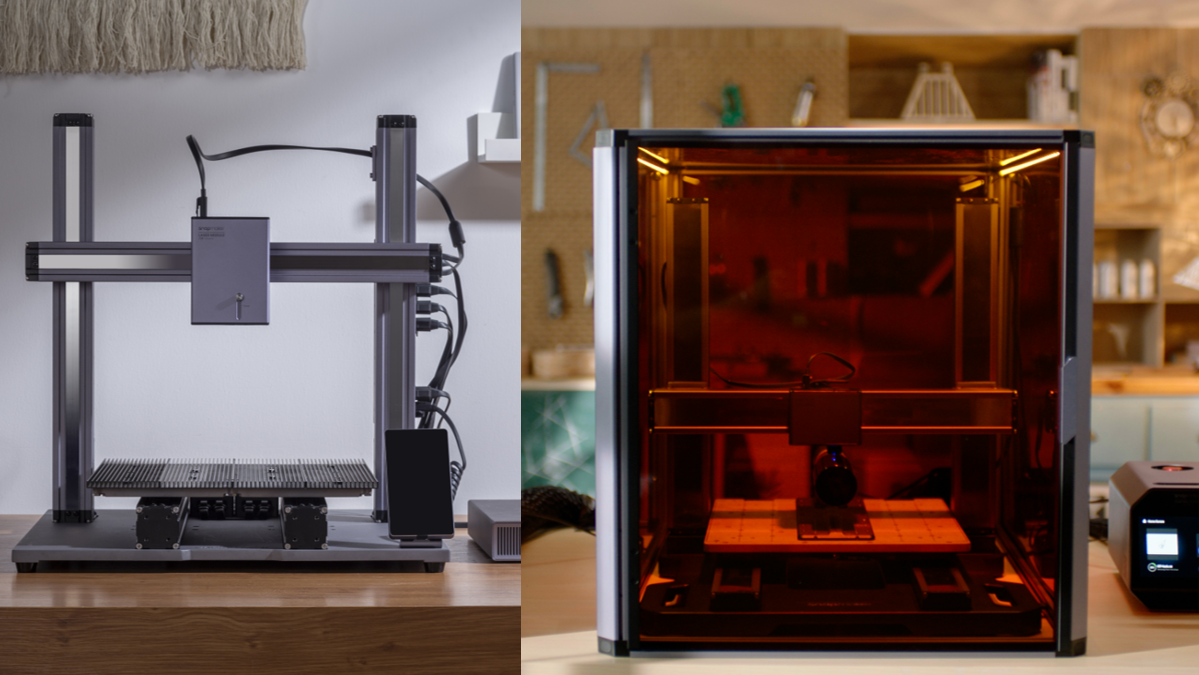

An open-frame 3D printer is exactly what it sounds like—its mechanical components and build area are exposed to the surrounding air. This design is intentional. By allowing for maximum airflow, it helps cool the extruded filament quickly, which is beneficial for certain types of materials.

How Enclosed Printers Create Stability

An enclosed 3D printer houses its entire build volume inside a case or cabinet, often with a clear door. Its primary function is to trap the heat generated by the print bed and hot end. This creates a consistently warm and stable chamber, protecting the print from outside temperature fluctuations and drafts.

How to Choose: Comparing the 4 Key Decision Factors

Your choice doesn't come down to which printer is "better," but which is better for you. Let's walk through the four factors that will make the decision clear.

Factor 1: The Materials You Plan to Print

This is the most critical factor, as your choice of filaments can make one printer type excel and the other fail.

- Open-Frame: The clear winner for beginner-friendly filaments like PLA, TPU, and most PETG, as these materials require good cooling to produce sharp, clean prints.

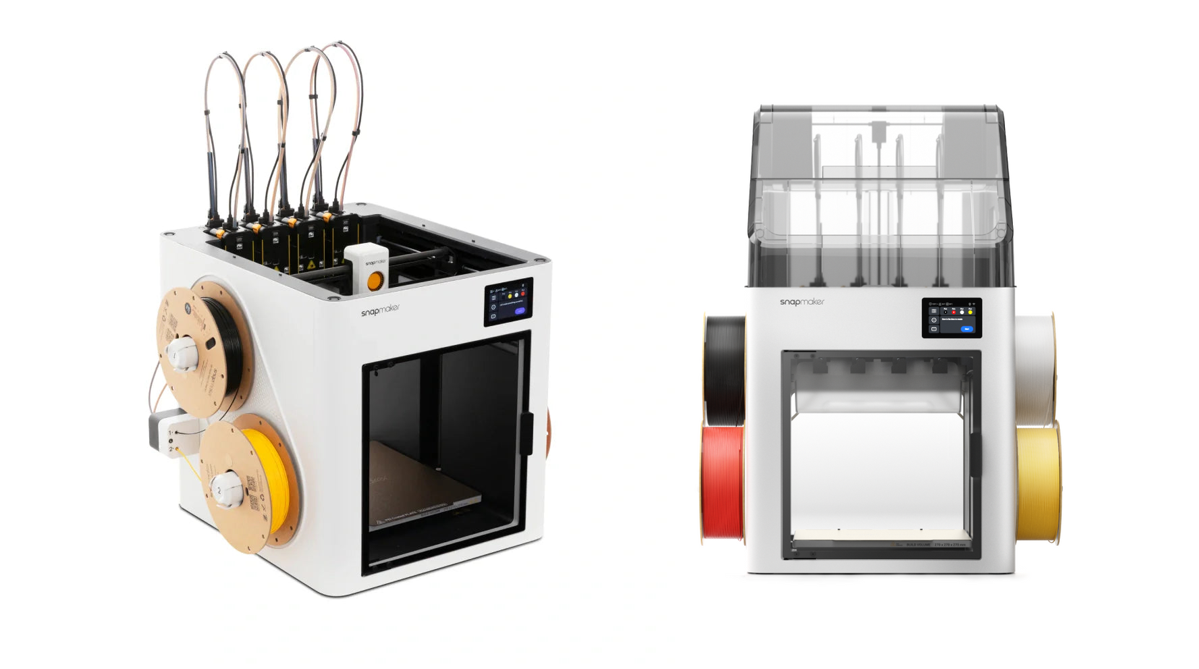

- Enclosed: Absolutely essential for high-shrinkage materials like ABS, ASA, and Nylon. These engineering-grade filaments shrink significantly as they cool. In an open environment, this rapid, uneven cooling causes internal stress that leads to severe warping. This is why a high-quality add-on enclosure for the Snapmaker Artisan is designed to create a fully sealed chamber that maintains stable temperatures, crucial for successfully printing these demanding materials.

Factor 2: Your Priority on Print Quality & Reliability

Are you willing to troubleshoot issues, or do you need prints to succeed with minimal fuss?

- Enclosed: Offers superior reliability and consistency. By eliminating environmental variables like room drafts and dust, an enclosure dramatically reduces the chances of random print failures. This stability also promotes stronger layer adhesion, resulting in more durable parts.

- Open-Frame: Can produce fantastic quality prints, but it is more sensitive to its surroundings, requiring a more controlled room environment for best results.

Factor 3: Your Printing Environment (Safety, Fumes, & Noise)

Consider the practical realities of where your printer will live and who will be around it.

Enclosed: The responsible choice for a multi-use environment. Key benefits include:

- Safety: The casing provides a physical barrier, protecting curious children or pets from extremely hot and fast-moving parts. Overall printer safety is a key consideration in any home.

- Fume & Odor Control: Filaments like ABS release odors and potentially harmful volatile organic compounds (VOCs). An enclosure contains these, and many now incorporate filtration. For instance, an add-on like the Top Cover for the Snapmaker U1 includes a HEPA and activated carbon filter specifically to manage these emissions.

- Noise Reduction: The walls of the enclosure significantly dampen the mechanical noise of the motors and fans.

Open-Frame: Best suited for dedicated workshops, garages, or well-ventilated rooms where noise and access by others are not primary concerns.

Factor 4: Your Budget and Desire to Tinker

Finally, consider your budget and how hands-on you want to be with your machine.

- Open-Frame: Often the most budget-friendly option and the ideal platform for users who enjoy easy access for maintenance, learning the components, and installing modifications.

- Enclosed: Represents a higher initial investment and can have more constrained access, often appealing to users who want a more "set it and forget it" printing experience.

The Final Verdict: Which Printer Profile Fits You?

Now, let's put it all together. You should be able to see yourself clearly in one of these two profiles.

- The Open-Frame User Profile: You are likely a hobbyist, a beginner, or someone on a defined budget. You'll primarily print with PLA and PETG, and you value the ability to easily access and modify your machine.

- The Enclosed User Profile: You are likely a professional, an engineer, or a serious hobbyist who needs top-tier performance. You must print with demanding, engineering-grade materials like ABS and Nylon and prioritize print reliability, safety, and consistency above all else.

FAQ on Enclosed vs. Open 3D Printers

What is the main point of an enclosed 3D printer? The main point is to create a controlled, heated environment. This is essential for printing high-temperature materials like ABS to prevent warping, and it improves overall print reliability, safety, and fume/noise control.

Can you put an open 3D printer in an enclosure later? Yes, absolutely. This is a very popular and cost-effective upgrade path. Many modular systems are designed with this in mind. For example, for the new Snapmaker U1, a dedicated Top Cover is available to quickly and affordably convert it into an enclosed chamber capable of maintaining a passive chamber temperature of up to 50 °C for more demanding prints. Similarly, comprehensive add-on enclosures are available for machines like the Snapmaker Artisan to expand their material capabilities.

Are enclosed 3D printers much quieter? Yes, they are significantly quieter. The physical walls of the enclosure act as a sound barrier, dampening the noise from the stepper motors and cooling fans, which can be surprisingly loud during a long print.

Do enclosed 3D printers handle all the fumes? An enclosure contains fumes, but it doesn't eliminate them on its own. For effective fume and particle removal, you need a filtration system. Many modern enclosed printers and add-on enclosures—like the Top Cover for the Snapmaker U1—come with built-in carbon and/or HEPA filters for this purpose.