The Perfect ABS Filament Temperature: Mastering ABS Nozzle Temperature and Beyond

ABS filament is strong, heat-resistant, and built to last. It handles stress and higher temperatures better than PLA. That makes it ideal for parts that need durability or will face heat. But any 3D printing enthusiast knows ABS comes with challenges. Corners lift, layers crack, and the smell can be unpleasant.

Success with ABS depends entirely on heat. If the ABS filament is the right temperature, your print will stick, the layers will join, and it won’t warp. This guide will show how to get perfect prints with your Snapmaker, using the nozzle, bed, and air heat.

Setting the Core Heat — ABS Nozzle Temperature

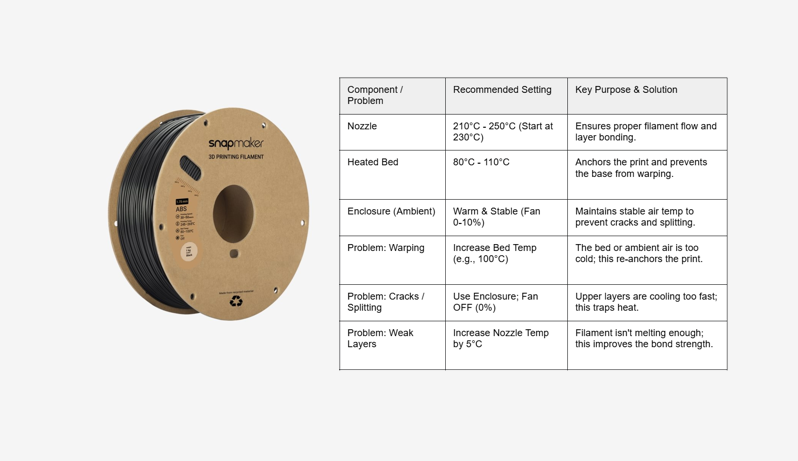

The nozzle is where your print starts. For ABS, set the nozzle temperature between 210°C and 250°C. This lets the plastic flow properly. Do not go below 210°C. Small changes in temperature can affect the print quality.

Start the ABS nozzle temperature at 230°C for a new filament. If the layers peel off, raise the heat 5°C. If you see blobs or strings, lower the nozzle temperature by 5°C. Don’t go below 210°C. Even a small change can turn a bad print into a clean, strong one.

Building the Foundation — The Heated Bed

The bed must stay warm. Keep the ABS filament temperature around 80°C to 110°C. ABS gets soft at 105°C. The bottom needs to stay hot so it sticks. If it cools too fast, the print can bend, twist, or fall off. The heat must stay strong to keep your print safe.

Adhesion aids improve success. Use PEI sheets, a thin layer adhesion of ABS juice (ABS dissolved in acetone), or a glue stick. These simple tools help anchor the print. The heated bed works with the nozzle to create a stable thermal base. One alone cannot prevent ABS warping; both are essential.

A warm bed also ensures the first layers are smooth. If the bed is too cold, the filament cools too fast, causing uneven surfaces and separation. With the right glass transition temperature, prints start perfectly and continue without major issues.

If it is clogged, it may decrease adhesion. Clean the nozzle thoroughly or replace it if it becomes completely clogged. This helps the plastic come out smoothly. How thick each layer is and how fast you print also matter. Printing a bit slower and a little hotter helps the layers stick better and stay strong. Combining the right temperature with proper print speed makes ABS much more predictable.

Locking in Consistency — The Snapmaker Enclosure

Even perfect nozzle and bed settings fail if the air is cold. ABS does not like big changes in heat. If it cools too fast, it can crack or split. The Snapmaker Enclosure helps keep it warm and safe. The enclosure maintains a warm, stable environment around the print. Snapmaker 2.0 models and newer hold heat steadily. Gradual cooling prevents sudden shrinkage and helps layers fuse tightly. For the best results, turn the part cooling fan off or set it very low (0–10%). Even a gentle breeze can ruin ABS prints.

The enclosure also allows longer, taller prints to succeed. Without it, tall parts often warp near the top. With a stable internal temperature, even complex prints hold their shape. This makes the Snapmaker enclosure a game-changer for ABS.

Troubleshooting Common Temperature-Related Failures

ABS problems often trace back to heat issues. Small fixes can prevent wasted filament.

Tip: Stuff like a shaky bed, cold air, or damp air can cause issues. Replace one thing at a time. Watch your print and write down what works. Soon you will know how to print perfectly every time.

Conclusion

ABS is challenging, but heat control makes it predictable. The ABS filament temperature includes the nozzle, bed, and ambient air. Snapmaker’s precise machines, combined with the enclosure, simplify ABS printing.

With the right settings, your prints stick, layers bond, and warping is rare. Complex, durable ABS parts become achievable.

Grab your Snapmaker. Make the nozzle and bed hot just right. Warm up the enclosure. Watch your prints come out strong and smooth. If you take care and pay attention, printing with ABS is not scary; it is fun and feels really good. Happy printing, and may all your ABS creations come out perfect.